Steering

Turn the front wheels from one extreme position to another and make sure they move smoothly, without jerking or jamming. Also make sure that the wheels and tires do not touch the body and suspension parts or brake hoses.

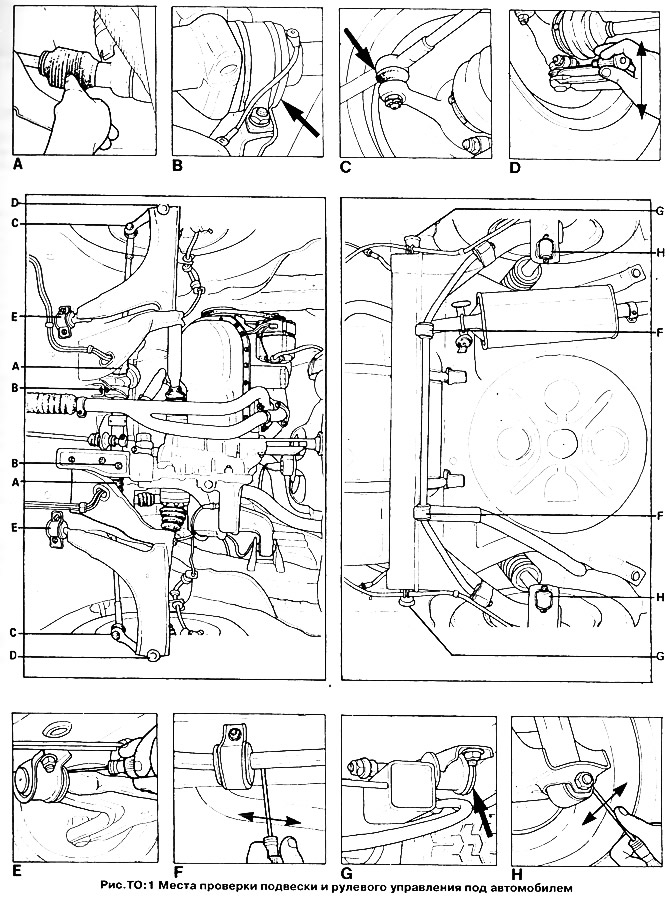

Check the condition of the rubber boots on the steering rack (A, Fig. TO: 1), ball bearings and tie rod ends - there should be no rubber cracks and grease leaks. Check the tightness of the steering gear mounting bolts, as well as the condition of the steering rod joints (E, fig. TO: 1) - there should be no appreciable play in the hinges.

Front suspension

Putting the lever under the wheel (the car is on the ground), try to lift each wheel in turn, while observing the mutual movements of the lower suspension arm and the telescopic strut or steering knuckle. In addition, the presence of ball joint play can be checked by trying to push the lower arm and telescopic strut apart with a crowbar (B, fig. TO:1).

To check the condition of the lower arm inner pivot bushing, try to move the arm relative to the suspension beam using a large screwdriver (C, fig. TO:1). Excessive play in the hinge indicates wear or destruction of the bushing, however, slight elastic movement is acceptable. Check the tightness of the front suspension bolts and nuts, and check the anti-roll bar bushings (in the presence of).

Rear suspension

Check the condition of the bushings of the rear axle hinges by pressing them with a lever or a large screwdriver from the brackets on the body and at the same time watching the mutual movement of the body and the rear axle (H, fig. TO:1). A slight elastic movement is allowed, due to the natural elasticity of the rubber bushings, but excessive play indicates wear and destruction of the bushing.

Check the tightness of the bolts and nuts of the rear suspension, as well as the condition of the bushings of the rear suspension struts (D, fig. TO:1).

Wheel bearings

All wheels should rotate smoothly, without jamming or knocking (remember that wheel spinning can be caused by brake pads rubbing against the disc or drum). Grasp the wheel with both hands and try to rock it in different directions to feel the play of the hub bearing (pic. TO:4). With excessive play, the wheel will noticeably sway relative to the hub axis, while a characteristic tapping is heard. Slight hub play is allowed

Telescopic stands (shock absorbers)

Inspect the telescoping struts for leaks of shock absorber fluid and for secure top and bottom mountings.

Suspension springs

Inspect the springs, looking for deep corrosion, cracks, and wear on the spring bearing surfaces.

If the car constantly leans to one side, it can be assumed that the corresponding spring is weakening. Remember that if one of the springs fails, both springs should be replaced at the same time (right and left).

Drive shafts

Inspect the rubber boots of the driveshaft joints (pic. TO:5) - there should be no cracks or leaks of lubricant. Check the condition of the hinges, for which try to turn the drive shaft and the hinge housing simultaneously in different directions, observing their mutual movement. There must be no play in the driveshaft joints. Check the hinges while the car is moving - wear on the outer hinges can be determined by characteristic clicks when the car accelerates through a sharp turn. Check the balance weight on the right drive shaft for 1.0L and 1.3L engines.

Brake pipes and handbrake cable

Inspect brake pipes and hoses (pic. TO:6). Deep corrosion and mechanical damage to tubes and hoses should not be. Have an assistant press the brake pedal and check for internal damage to the brake hoses, noticeable by the characteristic swelling of the hose when the pedal is depressed. Carefully inspect the system for fluid leaks. Check the tightness of the tubes.

Inspect the handbrake cables. Cables must not be severely corroded or mechanically damaged. Check the condition of the equalizer and pulley (pic. TO:7). Check the ease of movement of the cable.

Exhaust system

Carefully inspect the entire length of the exhaust system to identify areas of severe corrosion and exhaust leaks, visible as black soot spots. Check the reliability of the rubber suspensions, as well as the connecting clamps of the exhaust system (G, fig. TO:1).

Wheels and tires

As each wheel is rotated, inspect the rim and tire from all angles to assess the degree and uniformity of tread wear and any damage.

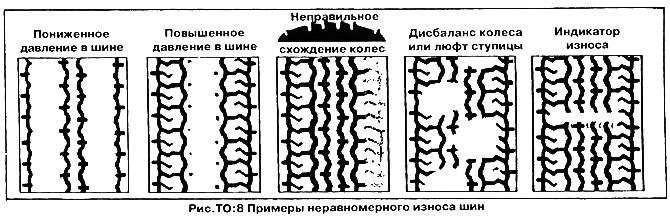

Causes of uneven wear include incorrect tire pressure, wheel imbalance, misalignment of wheels due to worn or damaged suspension and steering components, and worn hub bearings (pic. TO:8).

According to Russian regulations, tires must have a residual tread height of at least 1.6 mm; they should not have damage exposing the cord, as well as delamination of the carcass, delamination of the tread and sidewall. Disks and rims of wheels should not have cracks. In addition, if bias tires are installed on the car at the same time as radial tires, it is recommended to install radial tires on the rear wheels, and bias tires on the front.

Body

Carefully inspect the body for mechanical damage and corrosion. Particular attention should be paid to the attachment points of the suspension units, side members and body sills, as well as seat belts - severe corrosion in these places can make the operation of the car unsafe.

Visitor comments