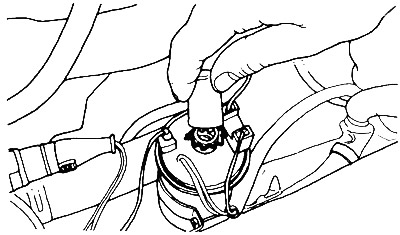

1. Checking for a spark at the output of the ignition coil

Remove the center high voltage wire from the distributor cap socket and keep it at a distance of approximately 6 mm from any metal part that is securely connected to "weight". Have an assistant turn the engine over with the starter. If the coil is working properly, between the wire and "weight" a strong bright blue spark should jump. Attention! This test cannot be carried out on vehicles equipped with an electronic ignition system. To avoid getting an electric shock, hold the wire with insulated pliers or, in extreme cases, through a thick, dry rag.

2. Check for spark on spark plugs

Disconnect the wire from one of the spark plugs. If you have a spare spark plug, connect the wire that was disconnected from the working spark plug to it and attach the spark plug to some unpainted metal part of the engine. Have an assistant turn the engine over with the starter. A strong spark should appear between the electrodes of the candle.

NOTE: To avoid electric shock, hold the wire with insulated pliers or, in extreme cases, by the insulated part of the cap through a thick, dry rag.

3. Checking the voltage at the input of the ignition coil

To check, you need a test lamp with two wires with clamps. Connect the lamp between the positive (+) ignition coil terminal and "weight". If the lamp is on when the ignition is on, then voltage is supplied to the coil. Disconnect the lamp wire from the positive terminal and connect it to the negative (-). If the lamp lights up, then there is no break in the primary winding of the coil, and the coil should work.

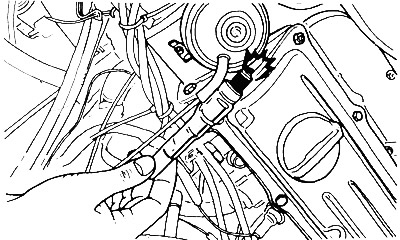

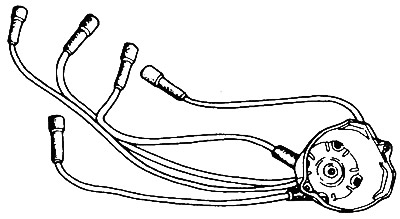

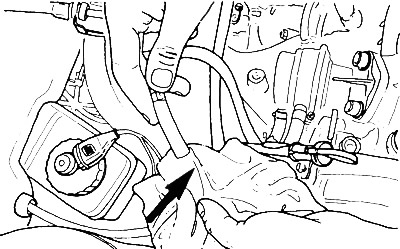

4. Checking the distributor cap and high voltage wires

Remove the caps from the candles, and then the distributor cap along with the high voltage wires. Wipe the wires, caps and cover inside and out with a dry clean cloth. In wet weather, it is recommended to treat the cover with a special water-repellent compound. Make sure that the cover, as well as the insulation and wire caps, are not cracked, frayed, or otherwise damaged. Check the condition of the carbon brush in the center of the distributor cap and its spring. Inspect the internal contacts of the cover - they should not have excessive erosion.

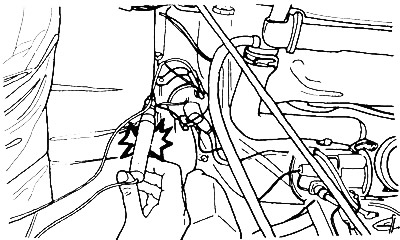

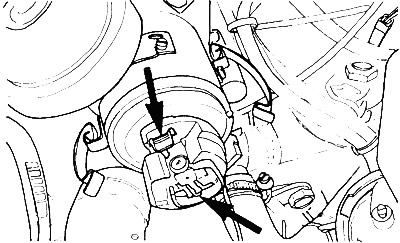

5. Checking the contacts of the breaker and the distributor rotor

With the distributor cap removed, rotate the engine, observing the breaker contacts, which should move (close and open).

Remove the rotor and inspect it. The rotor contact must not show strong erosion marks.

Inspect the contact surface of the breaker. In case of severe burning, clean the contacts with a thin file. If the contacts are badly burned or turned blue from overheating, then this may indicate a malfunction of the capacitor. Rotate the engine so that the moving contact block is at the highest point of the cam, adjust the gap between the contacts. Check if the moving contact or its wire is shorted to "mass". (Of course, all of the above applies to motors with contact (not electronic) ignition system. There are no breaker contacts on cars with electronic ignition)

6. Checking the fuel supply

Remove the fuel tank cap. If a vacuum is felt under the cork (when the plug is opened, air rushes into the tank), it means that they are blocked (clamped) fuel tank vent hoses or plug valves, which may well be the cause of the engine shutdown. Disconnect the fuel supply hose from the carburetor (or pressure regulator - on injection engines) and direct it into a wide container to avoid spilling fuel. Disconnect the wires from the ignition coil to prevent flashes in the cylinders, and check the fuel supply by turning the engine over with the starter (on carbureted engines) or by turning on the ignition (on injection engines). If the fuel supply is satisfactory, reattach the fuel line and remove the air filter. Opening the throttle and looking down into the carburetor, check if fuel enters the carburetor diffusers and then into the intake manifold (they must be wet with fuel).

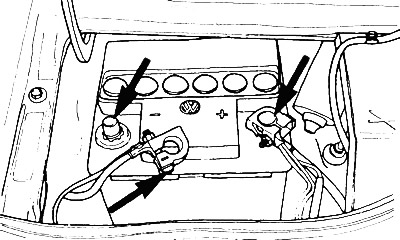

7. Check battery and wire connections "masses"

Make sure the battery terminals are securely tightened and not corroded. If any of the terminals gets very hot when the starter is running, then you can be sure that this is where there is an unreliable contact. Make sure the negative wire (the wire "masses") battery is securely attached to the body, and that the connection is not covered with corrosion products. If rust is present, sand the contact area to bare metal and tighten the joint securely. Check both ends of the wire in the same way "masses" engine.

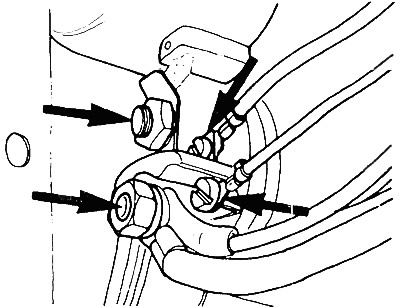

8. Checking the electrical connections of the starter

Make sure all starter connections are clean and tight, including the thick wires connecting the solenoid to the starter motor and battery. When the starter is turned on, a characteristic click of the electromagnetic relay should be heard. Check for voltage by connecting a 12-volt test lamp between the thick wire from the battery to the starter, and "weight". The lamp should burn brightly. Connect the lamp between two large (power) terminals of the electromagnetic relay. If the lamp does not light up brightly, then this means a malfunction of the starter (breakage of the winding, damage to the commutator or brushes). If the lamp is on, then when the starter is turned on (turning the ignition key) it should go out. If the lamp does not go out when the starter is turned on, then the electromagnetic relay is faulty (solenoid or contacts).

Visitor comments