Examination

Candles should be removed for inspection at the intervals prescribed "Maintenance Schedule".

Remove high-voltage wires from candles, holding on to the caps, because if you pull the wire itself, you can easily damage its inner core. Before removing the spark plug wires, mark them in order to install them in their original places. It is most convenient to mark the wires by gluing tags with the cylinder number to them with adhesive tape. Cylinder number 1 is located in front of the engine - on the side of the pulley and drive belts.

Before removing the spark plugs, clean the area around them of dirt with a brush or compressed air to prevent foreign particles from entering the combustion chambers.

To unscrew the candles, use a special candle wrench size 14 mm (pic. B:1). Be careful not to break the porcelain insulator when removing the spark plug.

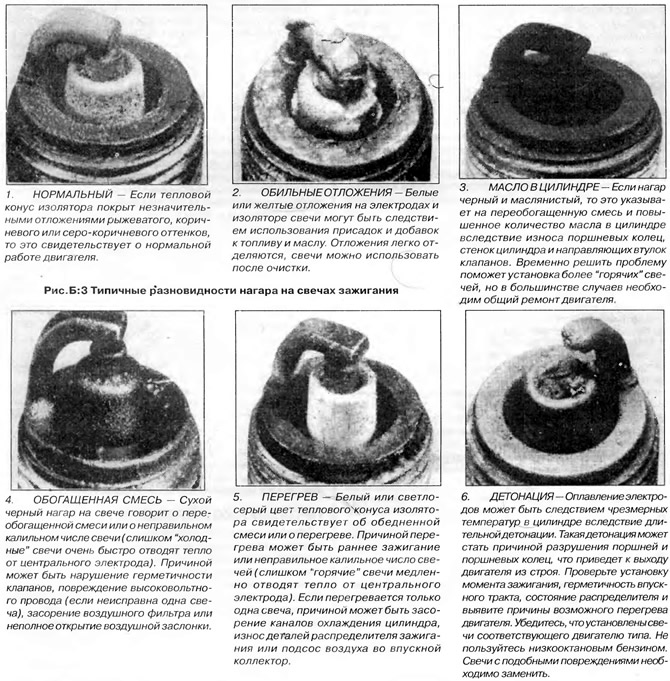

Inspect the insulator and electrodes of each spark plug. The condition of the spark plugs and the nature of the deposits on them indicates the general condition of the engine. Typical examples are shown in fig. B:3.

Gap between spark plug electrodes

Electrodes and spark plug insulator must be cleaned (best with a sandblaster). When cleaning the spark plug with a brush, the spark plug should be held with the electrodes down so that carbon particles do not get inside the spark plug body. If necessary, clean the electrodes of the spark plug with a flat file, giving a flat shape to the end of the central electrode. Check the performance of the pressure plug on a special stand. Candles that do not provide reliable neoplasm under pressure must be replaced.

The gap between the electrodes of the spark plug must correspond to that specified in the section "Technical data". An increase or decrease in the gap sharply reduces the effectiveness of the neoplasm.

Measure the gap between the electrodes with a round feeler gauge (pic. B:2). If necessary, adjust the gap by bending the ground electrode, making sure that the ground electrode is exactly opposite the center electrode. DO NOT ATTEMPT to bend the center electrode as this will destroy the insulator.

When installing new spark plugs, check and adjust the gaps between the electrodes. Make sure that the type of spark plugs matches those specified for this engine in the section "Technical data".

Clean the threads with a wire brush before installing the spark plugs. Screw the spark plugs into the holes in the cylinder head with your fingers and tighten them with a spark plug wrench by turning no more than a quarter of a turn. Do not overtighten the candles - this is important.

Visitor comments