Security measures

When performing any work on the electrical circuits associated with the generator, it is important to observe the following rules:

1. Never disconnect or rearrange the battery wires while the generator is running, otherwise the rectifier and/or voltage regulator may be damaged. It is undesirable to make any connection or disconnection in the charging circuit while the engine is running.

2. Never allow the generator to run with the power wire disconnected while the field windings are under battery voltage; otherwise, the rectifier diodes may be damaged.

3. When connecting the wires to the battery, always carefully observe the polarity of their connection - if connected incorrectly, the vehicle's semiconductor devices will be disabled (in particular rectifier diodes). It is recommended to connect the positive first (+) wire to positive (+) battery terminal, and then negative (-) wire in negative (-) terminal.

4. Always disconnect "mass" battery before connecting the charger to isolate the generator from the battery and external charger. The charger must be connected to the battery in parallel (positive battery terminal to the positive terminal of the charger, negative terminal to the negative terminal).

Verification procedure

1. Make sure the alternator drive belt is properly tensioned (see chapter "Vehicle maintenance work"). The battery must be in good condition, its terminals, as well as other connections and wires of the charging circuit, must be clean, securely tightened and make good contact.

2. Check the car's electrical system for leakage current, which can drain the battery while the car is parked and make it difficult to charge. Disconnect the positive wire from the battery and connect an ammeter between the wire and the positive battery terminahp electrical devices switched off (clocks, interior lighting, headlights, etc.) the ammeter should show a current of no more than 10 mA. If the current is high, find out and eliminate the cause.

3. Disconnect the wire connectors from the back of the generator, then connect the negative lead of the voltmeter to "weight" and turn on the ignition. Connect the second output of the voltmeter in turn to each of the disconnected wires of the generator. If there is no voltage on the blue wire coming from the warning light on the instrument panel, check the discharge warning light circuit and the light itself.

4. In the absence of voltage on the main (Red) charge circuit power wires to the starter, check wires and electrical connections between battery, starter and alternator.

5. If no fault is found, check the generator output current under load as follows:

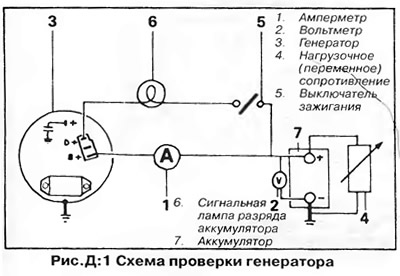

Disconnect the connectors and install a jumper between the blue wire and its terminal on the generator. Connect an ammeter between power (red) wires and their contacts on the generator. Connect a voltmeter to the battery terminals. Connect between the positive terminal of the battery and "weight" resistor providing a load current of 30 A in the circuit (pic. D:1). With an engine speed of 3000 rpm, headlights, heater fan and rear window heater on, the current at the generator output must correspond to that specified in section "Technical data".

To ensure the necessary power of the generator, the voltage between the battery terminals should not fall below 13 V. If the voltage is low, check the voltage regulator in the following order:

6. At an engine speed of 3000 rpm in a circuit assembled according to the diagram in fig. D:1, adjust the load resistance so that the generator output current is 25A (generator 35 A), 30 A (generator 45 A), 35 A (generator 55 A) or 45 A (generator 65A). With a good voltage regulator, the voltmeter reading should be between 12.5 V and 14.5 V. If the regulator does not provide the specified voltage, replace it.

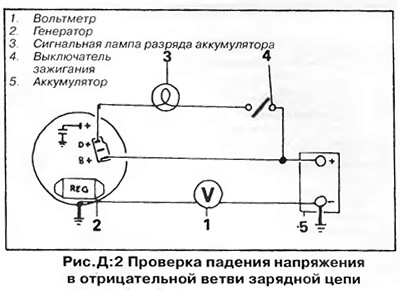

7. Check the voltage drop in the positive side of the charging circuit as follows:

- Assemble the control circuit as shown in fig. D:3. Start the engine at 3000 rpm and turn on the headlights. If the voltmeter reading is greater than 0.5 V, the positive branch of the charging circuit is faulty.

- If the positive side of the charging circuit is good, check for voltage drop on the negative side.

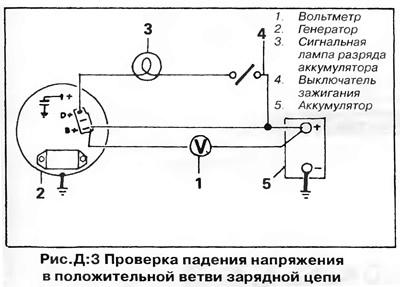

Assemble the circuit shown in Fig. D 2. If the voltmeter reads more than 0.25 V, the negative branch of the charging circuit is faulty - check the connections of the battery and the power unit with "weight".

NOTE: Most problems with the battery charging system are caused by worn alternator brushes or a defective voltage regulator.

Procedures for replacing the brushes and voltage regulator are described in this chapter. It is recommended that more complex troubleshooting be left to an auto electrician. It may be more economical than purchasing individual parts and repairing the generator to install a new generator assembly.

CAUTION: To prevent damage to semiconductor devices, ALWAYS disconnect the battery before doing any work on the electrical system.

Visitor comments