Removing

1. Remove the drain plug from the oil pan and drain the engine oil into a clean container.

2. Remove a gear belt as it is described earlier.

3. Remove the pulley bolt and remove the pulley and sprocket from the crankshaft.

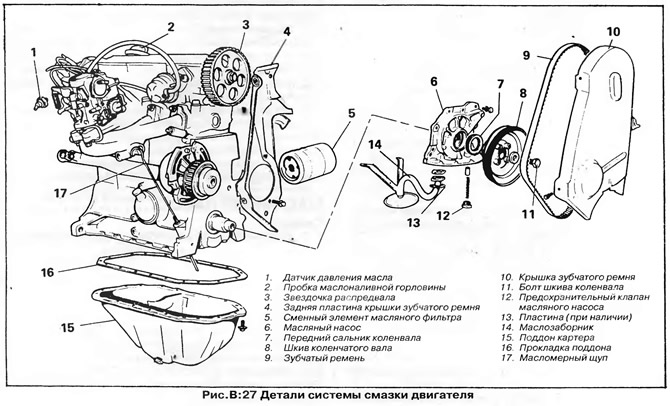

4. Remove the mounting bolts and remove the oil pan along with the gasket (pic. Q:27).

5. Remove the two bolts securing the oil intake struts to the cylinder block and the two bolts securing the oil intake flange to the oil pump.

6. Turn away bolts of fastening of the oil pump and remove the pump from a forward surface of the block of cylinders. Remove the oil pump gasket.

7. To facilitate access before removing the oil pump, you can first remove the back plate of the timing belt cover.

Inspection

The oil pump is supplied as a spare part only, so a defective or worn pump must be replaced as an assembly.

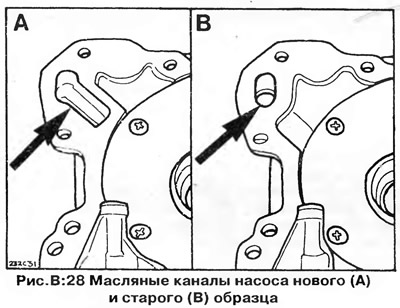

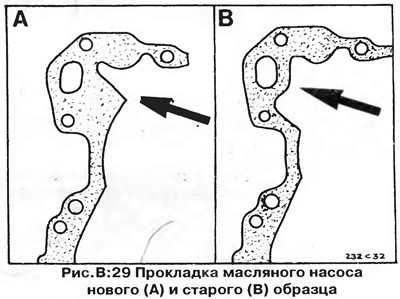

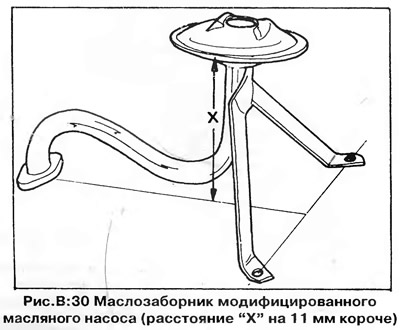

Since March 1977, a modified oil pump has been installed, featuring an enlarged, longer oil channel located on the mating surface with the cylinder block (pic. Q:28). When installing a new pump, it is necessary to install a corresponding new gasket (pic. Q:29), because the old type gasket with the new pump will not provide the required oil pressure. The new type gaskets can be used with both new and old pumps. In addition, a new oil pick-up is used with the new pump, the height of which is 115.0 mm, which is 11 mm shorter than the previous one (pic. At:30). Such an oil intake is installed in the presence of an oil pump and a new type of oil pan.

To remove the safety valve installed in the lower part of the oil pump housing, unscrew the plug holding it. Inspect the valve plug for wear or damage and check for a loose spring. Replace defective parts if necessary.

Installation

1. Make sure that the mating surfaces of the oil pump, oil pan and engine block are free of old gaskets.

2. Use new gaskets when installing pump and oil pan.

3. Clean the oil pickup strainer before installation.

4. Before tightening the bolts, check that the bottom edge of the pump housing is aligned with the bottom surface of the crankcase.

5. Tighten the sump bolts evenly to avoid deformation of the sump.

6. The tightening torque of the oil pump mounting bolts is 0.8 kgm.

7. Lubricate the surface of the crankshaft pulley mating with the oil seal, then insert the pulley into the oil pump housing. Tighten the pulley mounting bolt with a torque of 8.0 kgm.

8. Install the toothed belt as described earlier.

9. Tighten the sump bolts and fill the sump with the correct grade of oil in the required quantity (see section "Technical data").

Visitor comments