Removing

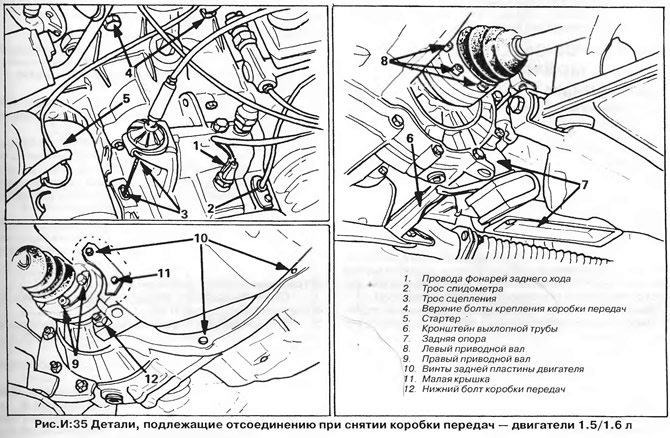

Parts that must be removed or disconnected when removing the gearbox from the vehicle are shown in fig. I:35.

1. Disconnect the wire "masses" from the battery.

2. Disconnect wires from the switch of lanterns of a backing.

3. Disconnect the speedometer cable from the gearbox. Seal the hole with a rubber plug to prevent oil loss and dirt ingress after the transmission has been removed.

4. Disconnect the clutch cable from the gearbox.

5. Disconnect the drive from the gearbox in the following order:

Remove the wire clamp and disconnect the top and trailing links from the gear selector lever. Disconnect the gear selector link from the rotary lever. Remove the tie rod assembly (see section "Gearshift drive").

6. Disconnect the wires from the TDC sensor (in the presence of) at the top of the clutch housing.

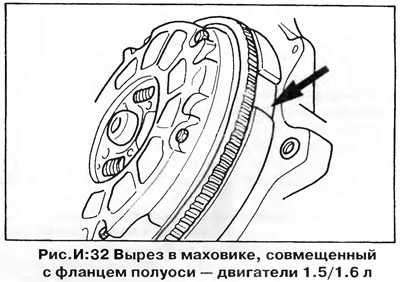

7. On vehicles with a 4-speed gearbox manufactured before November 1978, the gearbox has a stud located next to the flange of the right axle shaft, and in order to remove the stud from the hole in the engine, the box must be moved away from the engine strictly along the axis of the crankshaft. the flange of the right axle shaft could go past the flywheel, the latter has three cutouts (pic. I:32), and if the flywheel is not in the correct position, the flange will snag on the flywheel. Therefore, before removing the gearbox, it is necessary to remove the TDC sensor from the hole in the upper part of the clutch housing (or plastic cap) and turn the engine crankshaft so that one of the three protrusions (B, fig. D:44) or risk (Ah, fig. D:44) on the flywheel is aligned with the TDC indicator on the clutch housing (rice. D:44). These marks should not be confused with the 0-shaped TDC mark (one of the protrusions is at 76 BTDC) Once the flywheel is in this position, the engine should not be turned over.

8. On later vehicles, the stud has been replaced with a bolt and nut, and it is not necessary to install the flywheel in this way, since the gearbox can be rotated when removed. On injection models, the flange of the right axle shaft has a cutout, which should be turned towards the flywheel.

9. Support the weight of the engine with a hoist or jack placed under the wood-lined oil pan next to the transmission.

10. Disconnect the transmission support bracket from the top of the crankcase and body side member.

11. Turn away two top bolts of fastening of a transmission to the engine.

12. Disconnect wires from a starter, remember their arrangement. Remove the starter.

13. Detach the torque arm (power unit front mount) from the gearbox housing and from the body.

14. Disconnect the wire "masses" from the gearbox housing.

15. Remove the exhaust pipe bracket (in the presence of) from the main gear case.

16. Disconnect a back support of a transmission from a case of the main transfer and a body.

17. Disconnect the left drive shaft and hang it to the side on a wire hook (see chapter "Front suspension").

18. Disconnect the right drive shaft and hang it out of the way.

19. Turn away three screws of fastening of the back plate of the engine covering a crankcase of coupling. When removing the gearbox, the plate remains on the engine.

20. Turn out the remained screw holding the small cover which is behind a flange of the right semiaxle, and remove a cover.

21. Unscrew the rear (lower) nut (or bolt) fixing the gearbox to the engine.

22. Press the gearbox off the dowel pins and lower it down (see points 7 and 8). Due to the heavy weight of the gearbox, this operation should be carried out by two people, especially if a jack is not available.

Installation

The gearbox is installed in the reverse order. Pay attention to the following:

- A) On early production vehicles, before connecting the gearbox to the engine, one of the flywheel cutouts must be aligned with the flange of the right axle shaft (see fig. I:32).

- b) Raise the transmission and slide it onto the dowel pins. Make sure that the back plate of the engine does not move from its place.

- V) Align engine and transmission before final tightening of torque rod bolts and transmission mounts. The transmission support bracket must be centered on the body bracket and the torque arm must be centered on the bracket to which it is attached (see chapter "Engines 1.1/1.3").

- G) Tighten bolts and nuts of fastening with the moment specified in section "Technical data".

- d) Adjust the shift actuator as described by Bailie.

- e) Check the free play of the clutch pedal, if necessary adjust the cable as described earlier.

- and) Check the oil level in the gearbox and final drive (see chapter "Vehicle maintenance work").

Input shaft oil seal

To replace the oil seal, you need to remove the gearbox from the car.

Remove the oil seal from the socket by pressing it out with a thin screwdriver or pulling it out with a wire hook. Fill the space between the lips of the new oil seal with multipurpose grease. Also lubricate the lips and outer surface of the seal. Press the oil seal into place evenly, without distortion, using a mandrel (piece of pipe) the desired diameter.

Axle flange seals

The axle shaft seals can be replaced without removing the transmission from the vehicle. Disconnect the drive shaft from the axle shaft flange as described in chapter "Front suspension".

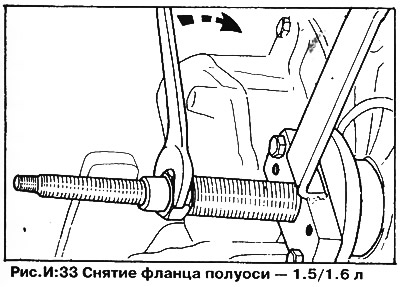

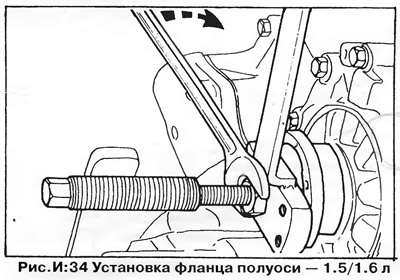

A puller is required to remove and install the axle shaft flange (pic. I:33, I:34)

Place an oil collecting pan under the axle shaft flange. Remove the plastic cover from the center of the flange, remove the circlip and washer that secure the flange to the axle shaft. Remove the flange with a puller (in fig. I:33 the puller is attached to the flange with two M8x30 bolts).

Pull out the seal using a screwdriver or hook. Fill the space between the lips of the new oil seal with multipurpose grease. Also lubricate the lips and outer surface of the seal. Press the seal into place until it contacts the bearing outer race.

Install the axle shaft flange and press it onto the axle shaft splines using a puller (pic. I:34). Install the cup washer, then install the circlip into the groove of the axle shaft. Make sure the Belleville washer is concentric. Replace the plastic cover.

Check the oil level in the gearbox, add oil if necessary (see chapter "Vehicle maintenance work").

Visitor comments