Removing

Before removing the clutch, you must remove the gearbox (see later in this chapter).

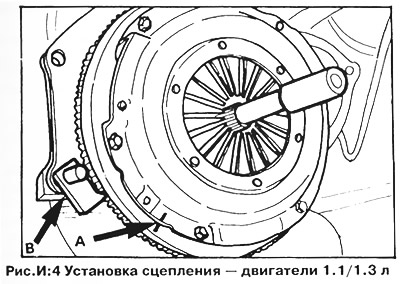

1. Mark the relative position of the drive plate and the flywheel to ensure proper assembly in the future (Ah, fig. I:4).

2. Fix the flywheel with a screwdriver or a special locking device (B, fig. I:4). Loosen the six drive disc mounting bolts. Loosen the bolts evenly, in a diagonal sequence, to avoid bending the clutch cover.

3. If the bolts have a socket head, a 7mm hex wrench will be required.

4. While holding the drive disc, remove the bolts and remove the drive disc from the flywheel together with the clutch driven disc. The drive disc is fixed to the flywheel with three dowel pins.

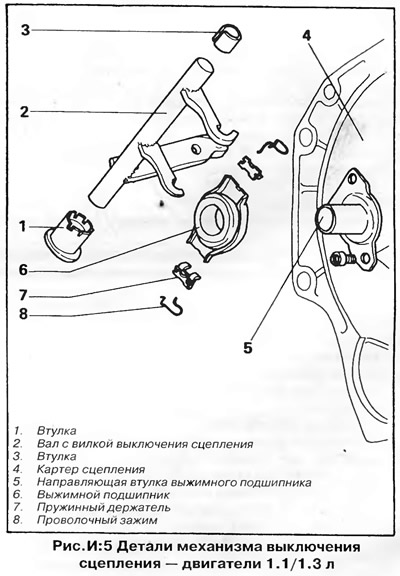

5. The release bearing is located in the clutch housing near the gearbox input shaft. To remove the bearing, you need to release the clips that secure the bearing to the clutch release fork (pic. I:5). Mark the position of the clips before removing, then press down on the lower end of the wire retainer to release it from the fork and remove its upper end from the bearing race. Remove the bearing.

6. Inspect the clutch parts as follows:

Driven clutch disc

The driven disc is one of the most important parts of the clutch, which is most prone to breakdowns.

Inspect the friction linings on both sides of the disc for wear, scorching, or oil contamination. If the pads are worn down to the rivet heads or have any of the other defects listed above, replace the disc.

If the disc is contaminated with oil, identify the source of contamination and eliminate its cause - only after that you can install a new disc. Disc contamination with oil can occur due to a defect in the gearbox input shaft oil seal or the crankshaft rear oil seal (oil seal replacement is described in chapter "Engine 1.1/1.3", and also in this chapter).

Before installing the disc, make sure that its hub slides freely over the splines of the gearbox input shaft without excessive lateral play.

Drive disc

Inspect the working surface of the pressure plate for scratches, scuffs or other damage, especially if the clutch driven plate linings have been worn down to the rivets. Replace the drive disk if defects are found.

Inspect the diaphragm spring tabs for wear where they contact the release bearing. Check the strength and reliability of the rivets, as well as the junction of the spring with the pressure plate and clutch cover.

If there are damaged parts, replace the entire assembly.

If there are no external defects, check the warping of the pressure plate (using a steel ruler and probes). If the height of the roughness exceeds 0.3 mm, replace the drive disc.

Flywheel

Inspect the friction surface of the flywheel in the same way as the pressure plate. For deep scratches, nicks, cracks or signs of overheating (bluing or small cracks are acceptable) remachining the flywheel or replacing it.

Release bearing

Inspect the release bearing for wear, damage or play. Holding the bearing by the inner ring, rotate the outer ring of the bearing while pressing it along the axis. Replace the bearing if rotation is difficult or noisy, or if the bearing lacks lubrication (the bearing has a lifetime supply of lubricant, and its lubrication during operation is not provided).*Do not wash the bearing in solvent, as this removes the grease it contains. Check the outer surface of the guide bush for nicks or burrs. The bearing cage should slide freely, without jamming, along the sleeve. Do not lubricate the plastic bushing.

Installation

1. To correctly align the clutch disc with the flywheel, use a special tool (mandrel) to center the clutch (pic. I:4). If the disc is not centered when installing the clutch, then later on when installing the gearbox, great difficulties will arise.

2. In February 1978, the diameter of the pilot hole in the end of the crankshaft was increased from 15 mm to 21 mm - make sure that the diameter of the mandrel matches the diameter of the hole.

3. Clean the friction surfaces of the flywheel and drive plate from oil and dirt residues.

4 Install the clutch disc onto the flywheel. The side of the disc hub facing the flywheel is usually marked. Center the disc by inserting a mandrel into it, and install the drive disc on the flywheel.

5. When installing the old drive disc, align the marks made before removal (Ah, fig. I.4).

6. Establish bolts of fastening of coupling and tighten them in diagonal sequence gradually, with the moment of 2.5 kGm. Remove the centering tool.

7. Assemble the release bearing with the clutch release fork. The lower ends of the wire clamps should engage with the fork.

8. Grease with molybdenum grease all rubbing surfaces of the clutch release mechanism, including the outer contact surface of the release bearing.

9. Install the gearbox as described below and adjust the clutch cable.

Visitor comments