Raise the car on stands.

Fully release the handbrake.

If necessary, firmly press the lever of the brake force regulator once by hand (see «Checking the brake force regulator») in the direction of the rear axle, otherwise, due to possible residual pressure in the brake system, the right rear wheel brake will begin to operate without further adjustment.

On the inside of the wheel, sleep the rear (looking in the direction of travel) plastic stoppers.

In order for the linings to be closer to the brake drum, it is necessary to turn down the adjusting nut, which has a splined surface.

Turn the adjusting nut further with a screwdriver: tooth by tooth.

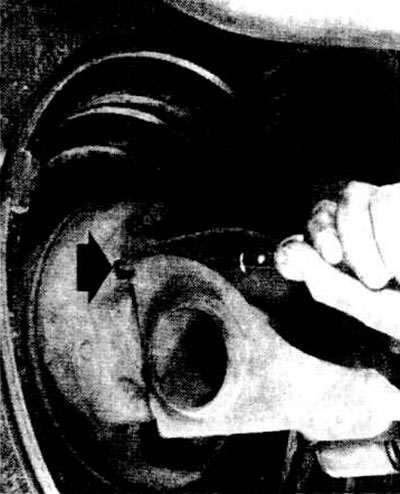

To adjust the drum brakes, insert a screwdriver into the hole located at the rear (if you watched» in the direction of travel) in the base sheet. There is a toothed adjusting nut on the back.

If the adjusting nut is rusted, you need to put a powerful screwdriver to the tooth and hit the screwdriver shaft with a hammer.

If this does not help, remove the brake drum and try with a rust remover to ensure that the adjusting mechanism moves easily. Caution: solvent must not get on the linings.

Turn the adjusting nut until the wheel can no longer turn - now the linings are adjacent to the drum.

Again turn the nut back until the wheel can be turned. Pay attention to the noise during rotation.

Automatic gap adjustment on models manufactured after August 1978

Since August 1978, drum brakes with an adjusting wedge have been used in the machines. This design more than ns required additional adjustment. This was due to simple mechanics. The push rod, located between the brake shoes, must lengthen as the lining wears, so that they again lie against the drum. This is done by means of a spring-loaded wedge that advances in the stem as the pads wear down gradually.

Visitor comments