- terminal 53 receives voltage for the first wiper speed;

- terminal 53a supplies current for the wipers to reach their end positions (stop);

- terminal 53b supplies voltage to drive the brushes at 2nd speed;

- Via terminal 53e, the wiper motor is braked when reversing after switching off, so that the wipers do not go beyond their end positions.

If the wipers do not reach their end positions when switched off, the wiper motor receives voltage from terminal 53a via a sliding contact until the wipers are in their end positions.

Instruction. With the ignition on, the wiper blades must not be blocked beyond their end positions (e.g. due to snow or freezing). Then terminal 53a continuously supplies voltage. Since the wiper motor cannot run due to blocked brushes, it burns out after a certain time, in which case it is necessary to lift the brushes so that they can be in the desired end positions.

Removing the wiper motor

Open the engine hood.

Remove the wiper motor connector.

Move the right and left drive rods from the crank arm.

Loosen the 3 motor mounting screws.

Remove wiper motor.

Before installing a new engine, connect the connector and let the engine run for a few minutes. When disconnected, it stops, and the wipers are in their final positions.

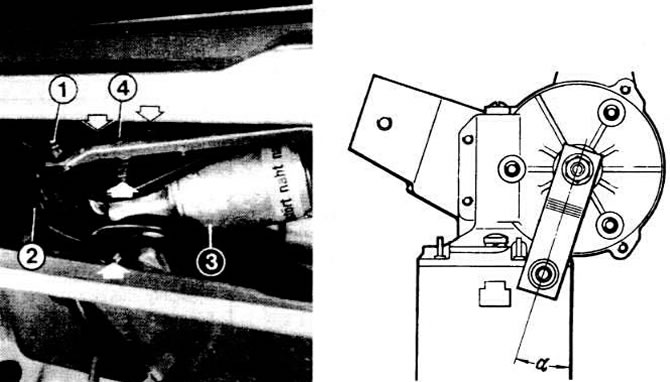

Crank arm in models "Golf" And "Jetta" set it up as shown in Fig. on right.

Lubricate hinges with MoS2 grease during installation.

Left: wiper motor (3): 1 - crank lever; 2 - rubber cover over the multi-pin connector; 4 - drive axle of the wiper motor. The arrows point to the screws that must be removed when dismantling.

Right: this is how the crank should be installed when the wiper motor is in the stopped position. The angle α is 20°.

Visitor comments