For adjustable cylinders, the camshaft eccentrics must point upwards (FROM). Now turn the corresponding cup pushers like this. so that they can be accessed from the right and left.

Turn the crankshaft further 1/4 turn. The piston is then no longer at top dead center. Therefore, the valves cannot collide with it when the pusher cup is pushed down with a key.

Put the key between both cams of the corresponding cylinder; both cup pushers are pressed down at the same time.

Attach special pliers to the cutouts of the cup pusher, lift the mounting plate.

When installed correctly, the washer is positioned in the cup pusher in such a way that the marking of its thickness is at the bottom.

If the washer is inserted incorrectly, then after the engine is running, the numbers on it can no longer be distinguished.

Calculate the thickness of the washer (see next section).

Insert a new washer into the cup pusher as follows. so that the numbers are at the bottom.

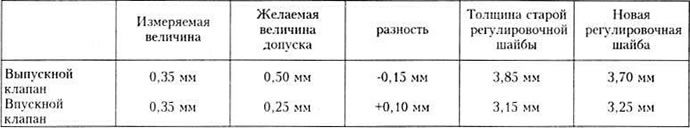

Choice of shim

If the expansion gap needs to be changed, the washer for the exhaust valve is selected in such a way that an upper tolerance value of 0.50 mm is reached due to the high temperatures that occur. At the intake valve, we set an average tolerance value of 0.25 mm. If the gap is too small, then a thinner shim is needed. If the gap is too large, the washer should be thicker.

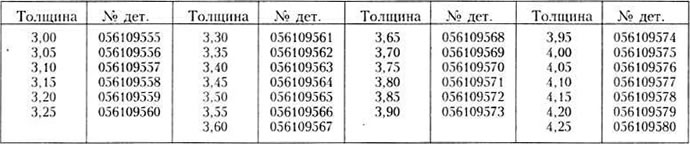

Here are two examples (Table 1). The following mounting plates are available (table 2).

Instruction. The new valve cover seal, as well as the cover itself, must be installed very carefully, otherwise oil may leak out. Don't forget about the gasket under the valve cover locknuts!

In a diesel engine, the valves are located next to each other in the cylinder head. Inlet placement order (E) and graduation (A) valves is as follows: A-E-A-E-E-A-E-A. For the best heat distribution, the exhaust valves are located on the outside of the engine.

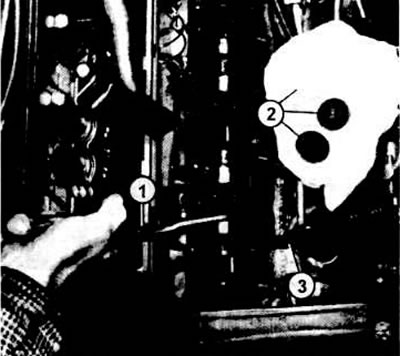

Pa illustration shows the adjustment of the valves of a diesel engine Key (3) press down on the cup pushers. So you can replace the mounting plates (2) using special pliers (1). When the plate is mounted, the indication of its size should be at the bottom

Table 1

Table 2

Visitor comments