Pumps fitted to these models between February 1979 and July 1980 cannot draw fuel themselves.

For injection system "Bosch":

- Unscrew the air release plug.

- Pull the handle of the hand pump until the fuel appears without air bubbles from the air outlet.

- Screw on the air release plug.

In the ''Lukas-CAV'' injection system, the hand pump is located on the fuel filter:

- Operate the pump until fuel free of air bubbles appears in the transparent hose leading to the high pressure fuel pump.

- Open the air release plug at the fuel pump 1-2 turns (see fig. at the bottom).

- Operate the starter for 15 seconds.

- Screw on the air bleeder again.

- Start the engine.

- If the engine runs intermittently, it is unstable - repeat pumping.

- For all injection system models:

- Escaping fuel should be collected in a small container.

Instruction. If, due to an oversight, completely unscrew the air bleed plug of the fuel pump "Lucas-SAV" diesel engine (1.5 l), then a steel ball may fall out (diameter 4 mm), sitting in the nozzle socket. The ball closes the vent hole in the nozzle when the plug is securely screwed on. If the plug is lost, the following malfunctions may appear: the engine does not start well or does not start at all, uneven idling, the engine stalls when the accelerator pedal is pressed, strong soot from the exhaust pipe.

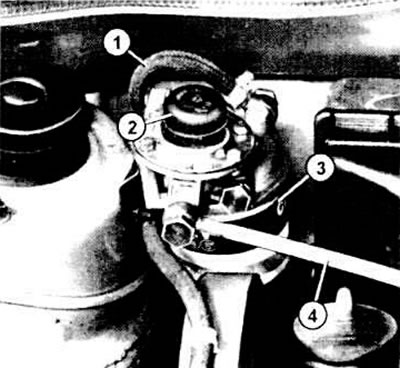

High pressure fuel pump bleed system "Lucas-CAV". Pump with a hand pump (2), located on top of the fuel filter (3), while in the transparent fuel line (1) there will be no air bubbles. Below is the fuel hose (1), leading from the fuel tank to the filter |

This photo shows the handle of the air injection plug (arrow) injection systems "Lucas-CAV" |

Waste disposal

When carrying out any work on the fuel system (water removal, ventilation, filter change) diesel fuel leaks out. It must be collected in a container.

Fuel lines

The diesel car has fuel lines: supply and drain. At the fuel tank, the hoses are fastened with clamps, at the fuel pump and at the filter with hollow bolts together with sealing copper washers.

Disconnecting the fuel line clamps

Pass a narrow screwdriver into the loop of the bracket, shifting to one side, disconnect.

Remove by rotating the hose.

If the hose cannot be removed, put a small wrench on the end of the hose, squeeze, turn.

During installation, threaded brackets are used instead of clamping brackets.

Checking the tightness of the fuel system

To search for leaks, the car should be left overnight on a dry, clean area.

Check if there are stains under the bottom of the machine.

If not, start the engine and let it run for a few minutes.

After switching off, check again under the bottom of the machine.

In case there are no stains again, check all pipelines and parts of the fuel system; Pay attention to whether there is a characteristic smell of diesel fuel.

Visitor comments