The fuel cools and lubricates the injector needles. Never inject all the injected fuel, the excess is drained back to the fuel tank through the drain pipe. The time interval between the start of injection and ignition is 0.002 sec.

In this case, even the slightest malfunction is very annoying. Then the nozzle needle sticks in the upper position, the cylinder either receives fuel unevenly or receives an excess of it; poor mixing with air occurs, uncontrolled ignition The result is poor engine performance. noise. similar to the one that appears when the crankshaft bearings knock.

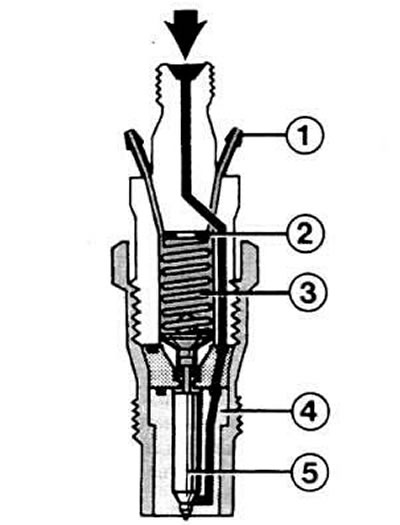

The section shows the nozzle: 1 - fitting of the drain fuel line; 2 - adjusting washer; 3 - nozzle spring; 4 - nozzle body; 5 - nozzle needle. The arrow indicates the path that the fuel travels under pressure. During injection, the nozzle needle is lifted from its place by fuel pressure. Then the diesel fuel is injected into the swirl chamber. Part of the fuel leaks past the needle back into the housing. Excess fuel from the nozzle is returned back to the tank through the drain pipe.

Knocking noise

Harsh combustion noise typical of diesel engines can still be heard on trucks today (their motors, as a rule. have direct injection without pre-chamber). Diesel engines of the described models are already "weaned" from this noise. Only during the warm-up period do they still remind of themselves with such knocking noise. In a warm engine, the noise is not very significantly different from that of a carbureted engine. It's annoying if the knocking still continues in a warm car.

The reason for the knock is too long a time interval between the start of injection and self-ignition of the mixture.

This may happen if:

- the nozzle needle is stuck;

- the fuel is flammable (e.g. summer fuel prone to waxing if driven at low temperatures);

- too much load and low speed;

- too low compression pressure.

Under certain conditions, it may be necessary to remove carbon deposits from the engine. Fast, long motorway driving often also helps, as a result of which deposits in the combustion chamber burn out.

Injectors are defective

A malfunction in a tone or other injector can be determined when the engine is running. In turn, at all nozzles, the union nuts of the high-pressure fuel lines are unscrewed and wrapped again. If a fuel line is disconnected from any injector, but the number of revolutions remains constant, then the injector is faulty.

Pay attention to injectors due to the following phenomena:

- permanently faulty glow plugs (see section "Defective glow plugs";

- strong black smoke from the exhaust pipe;

- high fuel consumption;

- engine overheating;

- strong knock;

- power reduction.

Visitor comments