Instruction. The distribution fuel pump is very sensitive to contaminated fuel. The hole in the clutch of the centrifugal regulator becomes dirty, wears out, as a result of which malfunctions appear in the engine. The pump cannot be repaired without a test bench, and this is costly. Therefore, it is best to regularly change the fuel filter, remove water from it.

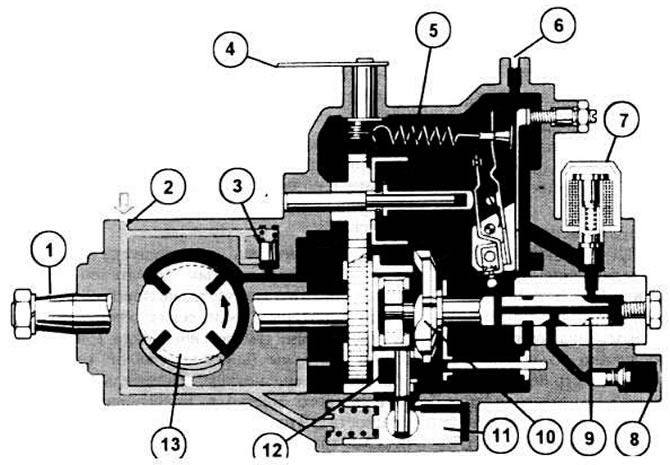

The illustration shows a sectional view of the high pressure fuel pump: 1 - drive shaft; 2 - fuel supply from the filter; 3 - fuel pump safety valve; 4 - manual feed control drive; 5 - centrifugal regulator; 6 - drain hole; 7 - switch; 8 - fuel line to injectors; 9 - distribution piston; 10 - push washer; 11 - injection advance regulator (rotated 90 degrees for better visibility); 12 - roller ring; 13 - fuel vane pump (also rotated 90 degrees)

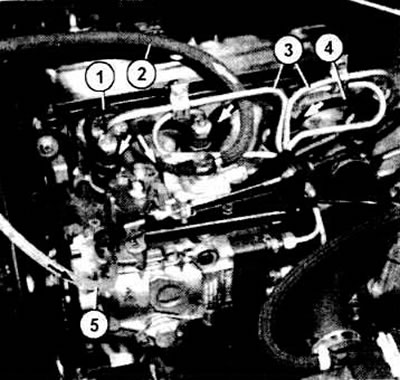

The illustration shows the fuel lines around the high pressure fuel pump: 1 - drain pipeline leading from the nozzles to the pump; 2 - drain pipeline from the fuel pump to the fuel tank; 3 fuel lines to injectors; 4 - drain pipeline between two nozzles; 5 - fuel supply line from the filter. The arrows show the direction of fuel flow. |

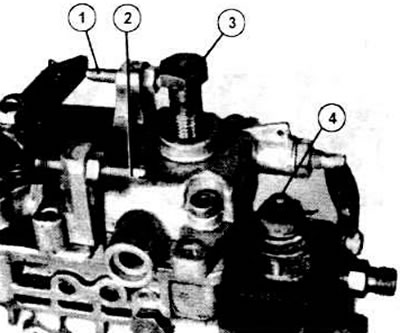

Drain pipe hollow bolt (3) shown lightly baited into the top of the fuel pump. You have to look very carefully to see a thin hole on the side of the bolt. On the top is engraved "ONT" in order not to confuse this bolt with another. After all, the hollow bolt of the supply pipeline looks similar, but it has a significantly larger hole diameter. Further, the numbers indicate: 1 - the minimum speed adjusting screw; 2 - adjusting screw for maximum speed; 4 - electromagnetic feed switch |

Visitor comments