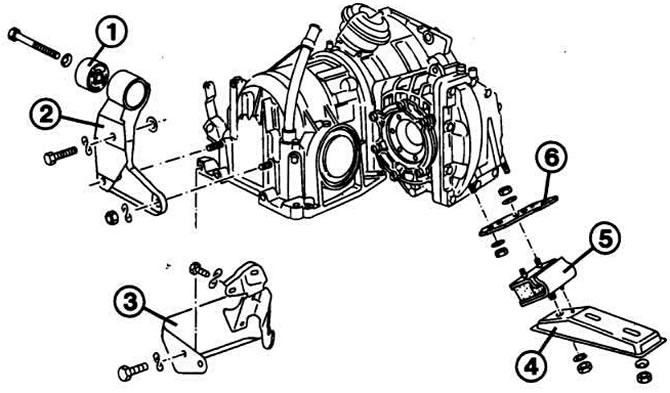

The automatic transmission has the following suspension parts: 1 - rubber-metal support; 2 - front support bracket; 3 - sheet covering for the gearbox; 4 - rear support; 5 - rubber-metal support; 6 - sheet for reinforcement

Disconnect the wires from the battery.

Unscrew the speedometer shaft near the gearbox.

Remove both upper bolts between engine and gearbox. Remove the support from the rear of the gearbox and from the body.

Remove half shafts.

Remove the starter: The third bolt is between the engine and the starter.

Remove the protective sheet of the crankcase and protection) - hydrotransformer coatings.

Through the starter flange, unscrew the three torque converter bolts; to do this, turn the motor 1/3 of a turn.

By setting the position "R", disconnect the cable ends from the control lever.

At the gearbox, remove the cable support.

Remove the pedal link and "gas" traction without changing their setting.

Remove the gearbox support to the left of the gearbox and from the body.

Remove the gearbox torque rod.

From below, support the gearbox with a jack through a wooden gasket.

Loosen the lower connecting bolt between engine and gearbox.

Use the mounting lever to move the gearbox away from the engine.

Pull the gearbox forward in the direction of travel on a jack against the engine flange and lower it carefully at the same time.

Fasten the torque converter firmly with a wire or cord so that it cannot fall out of the gearbox.

Before installing the gearbox, you must first correctly insert the transformer: rotate it slightly so that it sits as far as it will go on the so-called free-wheel support.

During installation, the same torques are prescribed as for a manual gearbox, see tables "Tightening torques for threaded connections", chapter "Gearbox and final drive".

After assembly, the workshop should check the adjustment of the bifurcated "gas" traction, as well as traction control lever.

Visitor comments