1. Remove the protection from the kingpin that secures the servo pusher 15 to the pedal 17 (pic. 8.2). The pin must be knocked out. Disconnect the pedal lever from the servo pusher in the same way.

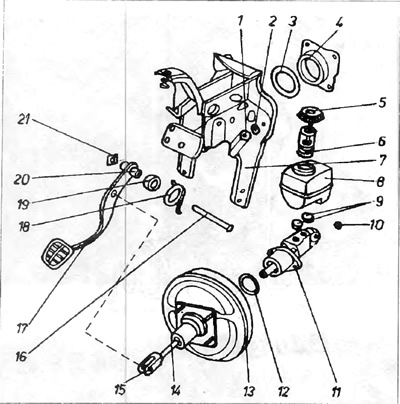

Pic. 8.2. Elements of the brake system

1 - fixing nut; 2 - washer; 3 - gasket; 4 - servo bracket; 5 - stopper of the fluid reservoir; 6 - liquid level sensor; 7 - pedal bracket; 8 - liquid tank; 9 - rubber gaskets; 10 - fixing nut of the cylinder; 11 - brake cylinder; 12 - gasket; 13 - servo; 14 - servo pusher; 15 - rod that secures the pusher to the pedal; 15 - kingpin (finger); 17 - brake pedal; 18 - return spring; 19 - bushing; 20 - pedal turnover axis; 21 - kingpin protection.

2. Remove protection 21 from kingpin 16, unhook spring 18 that lifts the brake pedal, knock out the kingpin and remove the pedal.

3. Check the condition of the working surfaces of the king pin and pedal bushing. The pivot must be cleaned and lubricated. When deep wear marks are clearly visible on the surface, and before disassembling the pedal dangled on the pivot, it is necessary to replace the pivot with a new one. If, after installing a new kingpin, the gap is still greater, then the bushing is worn out. It needs to be replaced.

Installation

4. Installation is carried out in the reverse order to dismantling. At the same time, it must be remembered that the surfaces of the bushing and the kingpin must be lubricated.

Visitor comments