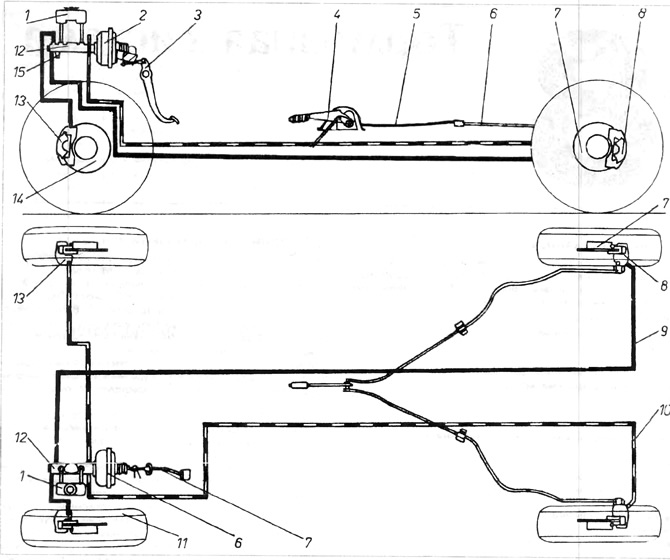

Pic. 8.1. Brake system diagram

1 - brake fluid reservoir; 2 - hydraulic vacuum booster - servo; 3 - brake pedal; 4 - hand brake lever; 5 - hand brake cable; 6 - metal protection of the handbrake cable; 7 - rear brake disc; 8 - rear brake clamp; 9, 10 - brake pipes; 11 - front wheel; 12 - brake cylinder 13 - front brake disc.

1. The main brake is controlled by pedal 3, which, through a pusher and a hydraulic vacuum booster - servo 2, drives a two-value brake cylinder 12. In the event of a malfunction of one circuit, the second makes it possible to stop the car. The brake system is divided diagonally one wheel front - one wheel rear

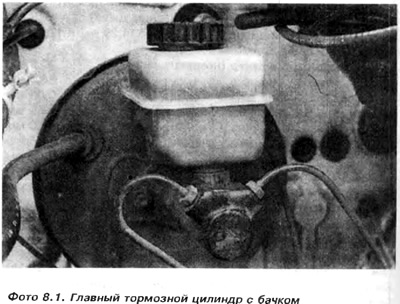

2. The brake fluid reservoir 1 is fixed to the brake cylinder 12. It is equipped with a float-type brake fluid level sensor that indicates a very low brake fluid level.

3. The brake cylinder creates pressure, which is supplied to the chain of the front wheels through the brake studs (in the figure is indicated by a solid line) and to the rear wheel chain (in the figure is indicated by a dotted line).

4. Hydraulic booster (servo) 6, fixed on the engine baffle wall, connected to the engine intake manifold. The main elements of the servo are the diaphragm and the shut-off valve. When the engine is not running, the servo does not work and effective braking requires more force on the pedal. When the engine is running, the reduced pressure is fed through channels to the two sides of the diaphragm. When pedal 3 is depressed, the space on one side of the diaphragm connects to the atmosphere. The pressure difference resulting from this provides an additional force that compensates for the force applied by the driver when depressing the brake pedal, which results in greater braking efficiency of the vehicle without the need for hard depressing the brake pedal.

5. Brake force corrector, available on some vehicles, reduces fluid pressure in the rear wheel clamps based on rear suspension deflection. With little suspension deflection due to a light rear axle load, the rear brakes should work less. When the pressure on the rear axle increases, the braking force increases, which automatically corrects the braking force. During heavy braking, the rear of the body rises slightly, causing a reduction in the load on the wheels of the rear axle. In vehicles without a corrector during hard braking, the rear wheels may lock up, thereby deteriorating braking performance. The corrector reduces the likelihood of the rear wheels slipping, which fundamentally improves the vehicle's stability during braking, especially on slippery surfaces.

6. Expanding devices 13 press the brake pads against the brake disc 14 through pistons, causing a braking effect. If you release the brake pedal, the pads move away from the disc every time by the same distance, regardless of wear. This maintains a constant gap between the intermittent gap adjustment discs. Brake pads in case of wear must be replaced with new ones. In some versions, spreaders are also available on the rear wheels,

7. Auxiliary brake (manual) only applies to the rear wheels. The handbrake is applied by lever 4, which pulls cable 5. The cable drives the rear wheel brakes. There is a switch under the lever. which turns on a light on the dashboard, signaling the tightening of the handbrake. The same lamp is connected to the circuit for signaling a very low level of brake fluid in reservoir 1 (pic. 8.1).

Visitor comments