Tires

1. Check and, if necessary, adjust the tire pressure. Check the condition and general wear of the tires. If the wear is uneven, it is recommended to have the tires inspected by a workshop to adjust the suspension geometry.

Suspension

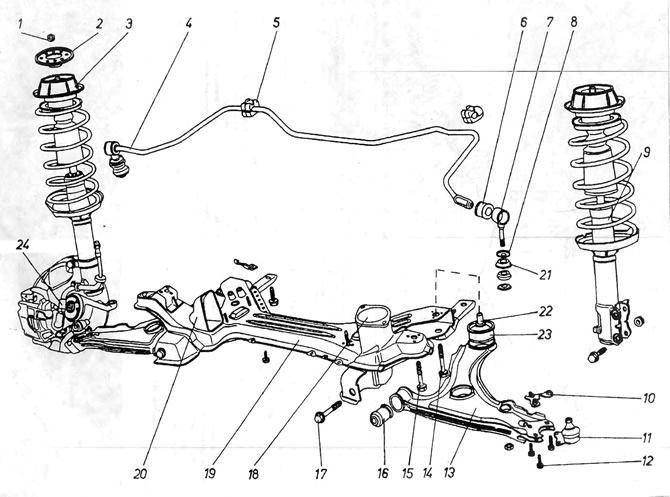

2. It is necessary to raise and put the car on stands, then inspect the parts that make up the suspension and control system for signs of excessive wear or damage. Check the ball joints 11 and suspensions, paying attention to the existing gaps and the condition of the rubber casings for signs of cracks and damage. If necessary, these parts are replaced with new ones. Check metal-rubber bushings 16 and 23, transverse 13 and stabilizer mounts 5 and 21, whether they are knocked out. If necessary, replace them with new ones. Check for signs of fluid leakage from the shock absorbers and signs of corrosion on the attachments of the suspension elements to the subframe and body.

Pic. 10.1. Front suspension

1 - column nut; 2 - fixing plate; 3 - support of the spring column; 4 - transverse stabilizer; 5 - pillow securing the stabilizer; 6 - rubber bushing; 7 - stabilizer connector; 8 - washer; 9 - steering rod (lever arm); 10 - clamping washer of the hinge; 11 - ball joint of the pivot pin; 12 - hinge bolts; 13 - lower balancer; 14 - bolt securing the rear metal-rubber bushing of the balancer; 15 - bolt securing the front metal-rubber bushing; 16 - metal-rubber bushing; 17 - axis of the lever; 18 - gearbox suspension bracket; 19 - auxiliary frame; 20 - engine mount bracket; 21 - rubber cushions installed with a cone towards washers 8; 22 - metal sleeve, removed when disassembling the balancer; 23 - metal-rubber bushing; 24 - brake pipeline.

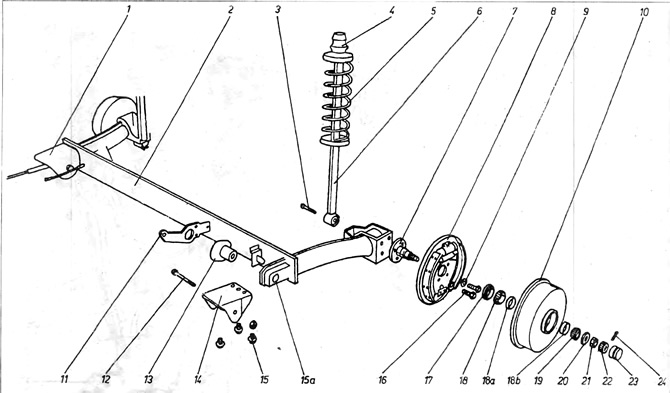

Pic. 10.2. Rear suspension

1 - hand brake cable; 2 - rear suspension beam; 3 - bolt securing the shock absorber; 4 - rubber cushions; 5 suspension spring; 6 - shock absorber; 7 - hub axis; 8 - disc that secures the brake pads; 9 - washer; 10 - brake drum; 11 - brake force corrector lever; 12 - rear beam bracket bolt; 13 - bushing metal-rubber suspension (shows the so-called protruding hub segment, which can be turned towards the front of the vehicle during installation); 14 - beam bracket; 15 - bracket bolts; 16 - hole in which the sleeve 13 is planted; 17 - bolts securing the axle shaft to the suspension beam; 18 - inner bearing; 18a - track of the inner bearing; 18b - track of the outer bearing; 19 - outer bearing; 20 - washer; 21 - hub nut; 23 - safety ring; 22 - hub cap; 24 - check.

Visitor comments