Extraction

1. Drain the liquid from the cooling system.

2. Take out the generator.

3. On vehicles equipped with power steering, you will need to remove the auxiliary pump with bracket to get to the water pump. On vehicles equipped with air conditioning, the compressor assembly with bracket will need to be removed.

Attention: Do not disconnect the wires of the air conditioning system.

To remove the water pump from the 1.6D engine, you must first remove the injection pump as described in section 1, otherwise you will not have access to the upper bolts securing the alternator bracket.

3. Disconnect three rubber coolant hoses from the pump, then unscrew and remove the four bolts securing the generator bracket and the water pump. To tear the pump from the block, it is necessary to knock on it with a copper hammer. Remove the o-ring with the pump.

Pump disassembly

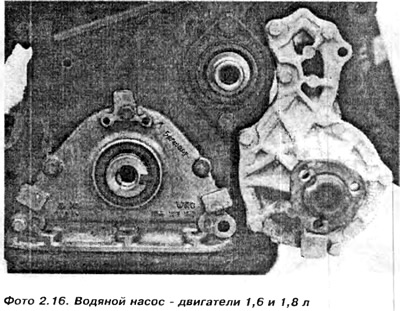

4. Remove the pulley and remove the eight bolts that secure the bearing cover and vane impeller to the water pump housing. Remove bearing cover with vane impeller (photo 2.16). Do not hammer a screwdriver to separate the water pump cover. Take out the old gasket.

5. Take out the thermostat.

6. In the water pump, the following elements are most often damaged - bearing, shaft seal or vane impeller. In case of damage to any element, all three of the above must be replaced.

Pump installation

7. Coat sealed surfaces with waterproof liquid and install a new gasket. Align the two parts of the water pump and tighten the bolts evenly with a torque of 10 Nm. Fasten the thermostat.

Installation

The pump is installed on the engine in sequence. reverse withdrawal.

1. First you need to put on a new o-ring type o-rmg Then put on the pump and install the generator bracket and screw with four bolts. Tighten the bolts with a torque of 20 Nm (photo 2.18).

2. Put on the alternator and tension the V-belt.

3. Fill the cooling system with liquid.

Visitor comments