1. Remove the cylinder head.

2. Unscrew and remove the oil pump.

3. Unscrew and remove the oil pump vessel with gasket.

4. Using a feeler gauge, check whether the connecting rod end clearance on each crank pin matches the dimensions specified in "Technical Data" (photo 1.124). If not, you need to check which element is responsible for the increased clearance and replace if necessary. It may happen that the connecting rod is thinner than necessary, or, more often, the width of the crankshaft trunnion has increased due to careless grinding.

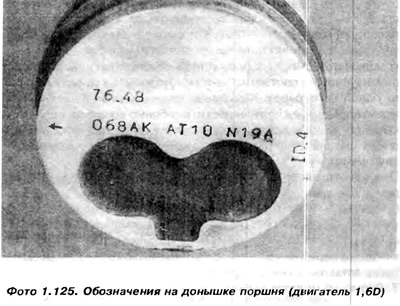

5. Before removing the head cover of the first connecting rod, it is necessary to rotate the crankshaft so that the piston is at BDC (bottom dead center). Pay attention to the designations that are on the connecting rod head cover, on the connecting rod rod, and also on the piston bottom. The arrow on the bottom of the piston points towards the timing belt (photo 1.125). The signs on the connecting rod and on the connecting rod head cover must also point towards the distribution belt (photo 1.126). This is intended to unambiguously determine the position of the piston and connecting rod with cap relative to a constant reference point. If these designations do not match, you can fill points from one to four with a center punch. Readable and unambiguous designations are essential especially during subsequent assembly. The cap cannot be rotated 180°relative to the connecting rod, nor can it be bolted to another rod.

The sequence of cylinders is as follows: the first is located near the timing belt, the fourth is near the flywheel.

6. To turn away nuts and to remove a cover of a crank head of a rod together with an insert. Pay attention to the tab of the liner that fits into the slot in the cover. It serves to block the liner before rotation. During installation, it must also be inserted into the socket (photo 1.127).

7. Use a hammer handle to knock out the piston and connecting rod from the cylinder.

8. Connect the cover to its connecting rod, paying attention to its position relative to the connecting rod rod. It should be the same as in the engine. To do this, use the points previously stuffed on the cover and on the top of the crank head before disconnection. The universal principle is to connect the cap, as in photo 1.128, so that the locks on both parts of the crank head of the connecting rod are on the same side.

9. Repeat the steps described in paragraphs 9.5-9.8 for pistons and connecting rods, first cylinder 4, and later, after turning the shaft, for cylinders 2 and 3.

10. The manufacturer recommends replacing the connecting rod bolts with new ones each time.

Visitor comments