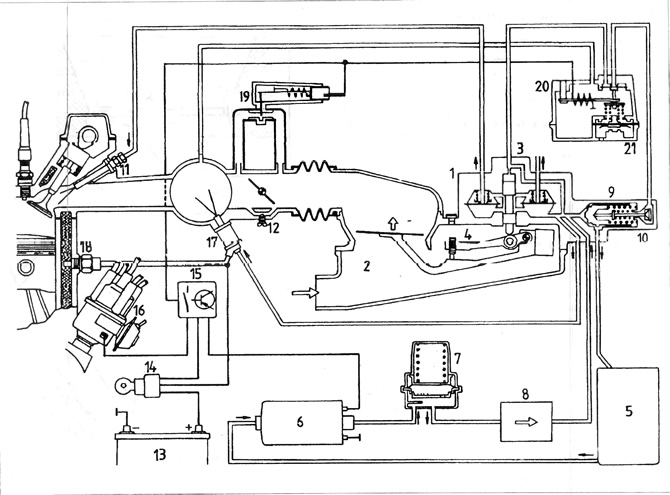

If the engine stalls after starting, switch 15, connected to the air flow meter plate, immediately turns off the pump

The fuel sucked from the fuel tank 5 by the pump 6 is supplied to the fuel pressure accumulator 7. The purpose of the pressure accumulator is to maintain pressure in the fuel system after the engine has been switched off so that the engine can be restarted immediately.

There is a fuel filter 8 behind the pressure accumulator. A regulator 9 is connected to the fuel pressure accumulator, which is integral with the fuel metering equipment 3.

When the engine is turned off, the pressure regulator makes it possible for the pressure of the fuel directed to the injectors to drop and cut off the flow of fuel through the injectors 11. This prevents spontaneous ignition. The pressure regulator closes just below the opening pressure of the injectors and this pressure is then maintained by a pressure accumulator.

Pic. 3.51. Scheme of the K-Jetronic injection system

1 - differential measuring valve; 2 - air flow meter; 3 - fuel distributor; 4 - adjusting bolt of the composition of the mixture; 5 - fuel tank; 6 - fuel pump; 7 - pressure accumulator; 8 - fuel filter; 9 - pressure regulator; 11 - nozzle; 12 - idle speed adjusting bolt; 13 - battery; 14 - ignition switch; 15 - switch disconnecting the fuel pump; 16 - ignition distributor; 17 - cold engine start valve; 18 - thermal time switch; 19 - additional air valve; 20 - engine heating valve.

Visitor comments