If the plate moves freely in the neck, then, together with the increase in pressure, the plate advances in the cone of the neck, and the surface between the edge of the plate and the cone increases until the moment when the pressure force and the reaction force of the plate are equalized. Thus, a measure of the amount of air entering the engine is the deflection of the plate. The air mass meter consists of an air inlet with a sensor plate mounted on a lever that is rotationally supported. The weight of the air flow meter sensor plate and the weight of its arm is compensated by the counterweight, and the upward force on the sensor plate is compensated by the weight of the moving piston. The piston, which moves up and down under the influence of air, is surrounded by a sleeve with longitudinal vertical cuts. The vertical movement of the piston causes the cuts to be opened to a greater or lesser length and thus the corresponding amount of fuel directed to the injectors is measured. The throat flank is not a normal cone, as optimum engine performance requires a different ratio of air to fuel under different conditions, such as idling. partial load and full load. Due to the fact that the part of the neck is made steeper than required in a normal cone, it is possible to obtain a richer mixture at idle and at full engine load. By making the neck flatter than a normal cone, a leaner mixture can be obtained.

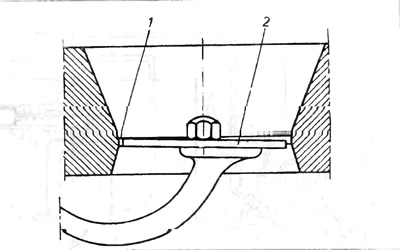

Pic. 3.49. Air mass meter

1 - the edge of the neck; 2 plate.

Visitor comments