2. Designate the relative position of the booster clutch and flywheel (photo 5.1).

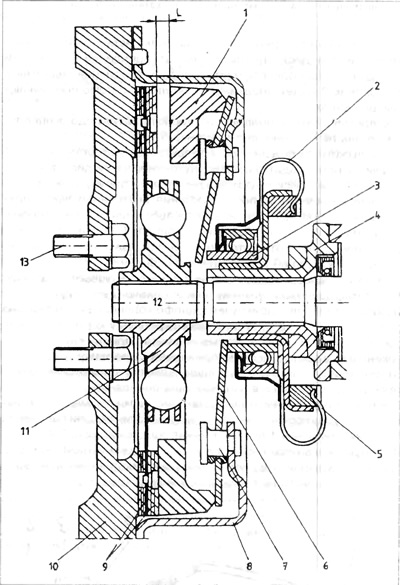

Pic. 5.1. Clutch Action Diagram - (pre-1985 solution)

1 - booster ring; 2 - spring ring; 3 - release clutch clutch; 4 - guide sleeve; 5 switching forks and disc spring; 7 - fastening rivet; 8 - clutch pressing housing; 9 - friction linings 10-flywheel; 11 - clutch disc; 12 - clutch shaft; 12 - bolts securing the flywheel.

3. Using a hex wrench, first loosen and then unscrew the bolts securing the clutch pressure to the flywheel. If necessary, block the flywheel with a screwdriver inserted between the teeth of the flywheel crown.

4. Remove booster and clutch disc from flywheel. Clutch disc hub that closes the cornering damper springs (rotations), facing the clutch booster.

5. Check the clutch elements.

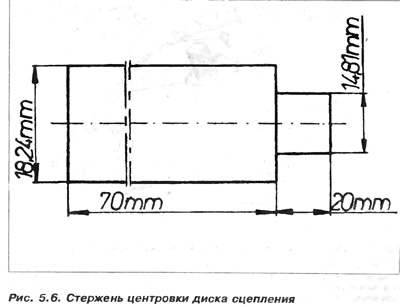

6. Before assembly, you need to find a tool for centering the clutch disc. If the disc is not centered, there will be problems when assembling the gearbox. Unlike typical solutions, the gearbox clutch shaft is not located at the rear of the crankshaft. If the clutch disc is not centered, there will be a problem installing the clutch cover onto the retaining studs. If a centering tool is not available, a rod with the dimensions given in figure 5.6 can be used.

Assembly

7. Clean the friction surfaces of the flywheel and booster ring, then fix the centering tool in the crankshaft trunnion and place the clutch disc on it.

8. Install the clutch booster on the flywheel (paying attention to the designations made during disassembly), then insert the bolts and evenly squeeze them crosswise with a certain moment

9. Before assembling the gearbox, check the release bearing as described in point 7.

Visitor comments