A) flywheel 10;

b) clutch disc 11;

V) clutch booster;

G) clutch release bearing 3;

d) guide sleeve and release bearing;

e) forks disengaging the clutch with lever 5;

and) clutch cable;

h) clutch pedals.

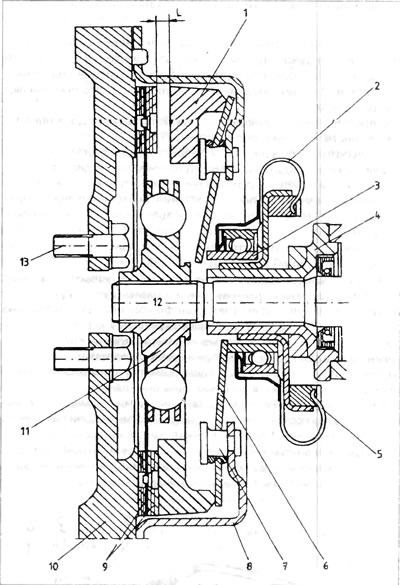

Pic. 5.1. Clutch Action Diagram - (pre-1985 solution)

1 - booster ring; 2 - spring ring; 3 - release clutch clutch; 4 - guide sleeve; 5 switching forks and disc spring; 7 - fastening rivet; 8 - clutch pressing housing; 9 - friction linings 10-flywheel; 11 - clutch disc; 12 - clutch shaft; 12 - bolts securing the flywheel.

The main element of the clutch assembly is the clutch disc. It transfers the drive from the engine flywheel to the gearbox clutch shaft. The clutch disc consists of a hub with an internal pin, a swivel shock absorber and friction linings. The hub is connected to the pads by means of a rotary shock absorber and springs that absorb sharp shocks of torque.

The swing damper consists of friction rings. which, moving relative to each other, dampen the vibrations of the shock-absorbing springs. The remaining elements serve to smoothly connect the engine to the gearbox in order to transfer the drive to the wheels of the car. The latest solutions for the clutch assembly provide ever greater reliability and ease of use for this assembly.

VW vehicles use two clutch circuit solutions. These two solutions use a disc spring as the actuating element. The disc spring has the best characteristic, which leads to the fact that the force produced by the clutch pedal travel is much less. This has the effect of higher clutch control comfort for the same torque transferred through the clutch. The first solution mentioned is the typical system shown in Figure (pic. 5.1)

When the clutch pedal is released, the disc spring 6 through the pressure ring 1 presses the clutch disc 11 to the flywheel. This is shown at the bottom of Figure 5.1. The rotational moment is transferred from the flywheel through the friction linings 9 and the clutch disc to the clutch shaft 12 of the gearbox. When the driver presses the clutch pedal, the release bearing 3 will be advanced along the sleeve 4 by means of the release forks.

The position of the release bearing after pressing the clutch pedal is visible at the top of figure 5.1.

When the release bearing moves towards the disc spring, the inside of the disc spring is bent. Since the spring disk is attached to the booster housing 8 with rivets 7, after bending the inner part of the spring, its outer part is bent in the opposite direction, pulling out the booster ring 1. After the booster ring is pulled, the flywheel rotates freely without transmitting torque to the clutch shaft. The second solution, shown in the figure, includes similar elements arranged slightly differently (pic. 5.2).

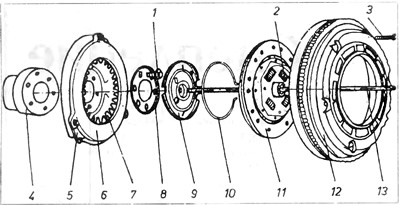

Pic. 5.2. Clutch elements

1 - a bolt securing the clutch booster; 2 - springs of the vibration damper when turning; 3 - bolt securing the flywheel; 4 crankshaft trunnions; 5 - clutch booster; 6 - booster ring, 7 - disc spring; 8 - washer; 9 - switching off disk; 10 - spring ring; 11 - clutch disc; 12 - flywheel; 13 - clutch pusher.

Clutch booster 5 is bolted to crankshaft trunnion 4 with bolts 1 and washer 8. Flywheel 12 is attached to clutch booster housing 5. In this system, flywheel is screwed to crankshaft trunnion and booster housing is screwed to flywheel.

The second fundamental difference is the use of a pusher located in the undercut of the clutch shaft.

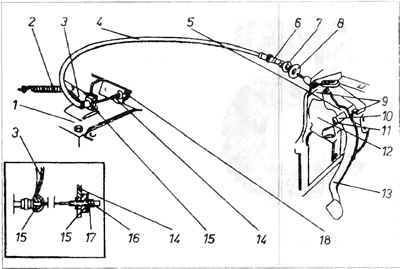

The release bearing and the release forks are housed in the rear housing of the gearbox. After pressing the clutch pedal 5, the clutch cable 1 rotates the clutch lever (pic. 5.4)

Pic. 5.4. External clutch release system - 084

1 - gearbox housing; 2 - tightening spring; 3 - switching off lever; 4 - clutch cable; 5 - clutch pedal arm; 6 - the end of the metal protection of the cable; 7 - fixing washer; 8 - pass; 9 - pedal stroke limiters; 10 - body of the kingpin of the pedal; 11 - king pin storage; 12 - tin partition of the engine; 13 clutch pedal; 14 - cable bracket; 15 - centering sleeve; 16 - locknut; 17 - adjusting nut; 18 - place for adjusting the length of the cable.

On the axis of the lever inside the gearbox, a shoulder is planted that moves the release bearing. The release bearing presses through the pusher 13 on the switching disk (pic. 5.2).

The switching disc bends the disc spring, which, like in the first solution, pulls back the pressure ring 6 and releases the clutch disc. The drive transmission is interrupted. The switching disk is attached to the disk spring with the help of a spring ring 10.

Visitor comments