2. Install the taper ring in the bearing of the differential mechanism and install the right drive flange, put the washer on the concave side of the flange and install the preliminary ring and plastic plug.

3. Install the output shaft with the tapered bearings in the clutch housing and gear it with the final drive gear.

4. Install the bearing retaining plate and tighten the bolts.

5. Install the 1st speed gear spacer on the output shaft with the concave side towards the tapered bearing.

6. Install the needle bearing and 1st speed gear and then the first synchronizer ring. Press the assembled synchronizer 1 and 2 speeds, making sure that the crackers are in the cutouts of the synchronizer ring. Before installation, the synchronizer must be heated to 120°C.

7. Install the reverse shaft together with the gear, install the reverse gear forks, notching them with the reverse gear.

8. Using a metal tube, drive in the inner race of the 2nd speed gear needle bearing, then install the needle bearing, synchronizer ring and 2nd speed gear.

9. Warm up the 3rd gear and press it onto the output shaft. Pick up and put on a new spring ring. The selected spring ring should be the thickest but one that would completely fit into the groove of the shaft and would eliminate the longitudinal clearance of the 3rd speed gear. Spring rings differ in thickness and are marked with different colors.

10. Install the input shaft into the clutch housing and gear it with the output shaft.

11. Warm up the 4th speed gear and press it onto the output shaft. Put on the spring ring.

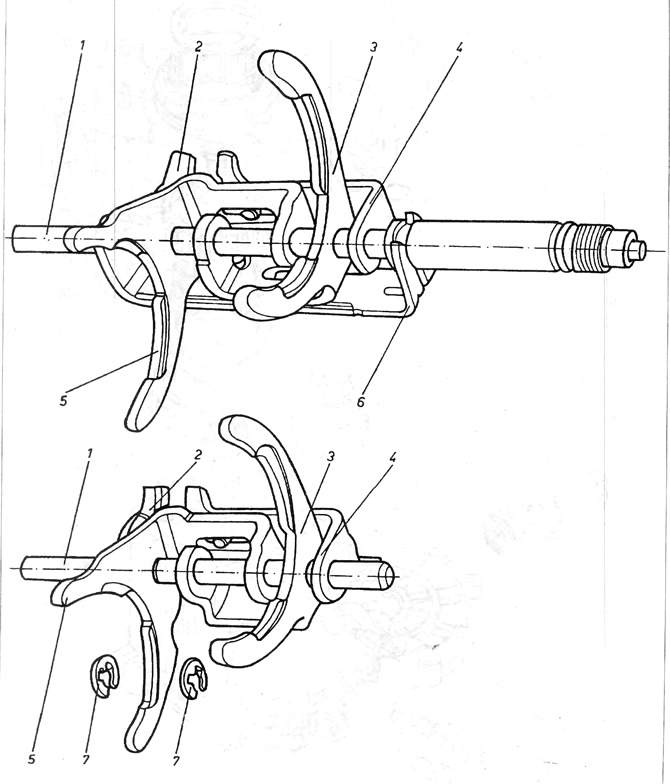

12. Install the slider shaft spring into the clutch housing, then secure the slider assembly. To do this, it is necessary to install the 1st and 2nd speed slider into the clutch groove, then install. 3rd and 4th speed slider and reverse slider engaged with reverse forks (photos 6.58 and 6.80).

13. Install the slider shaft into the clutch housing and set the cutouts in the forks in the neutral position.

14. The clutch housing and shafts are ready for the installation of the main gearbox housing.

15. Check the position of the reverse shaft (pic. 6.19).

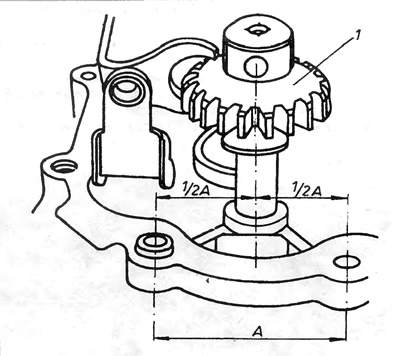

Pic. 6.19. The position of the bolt hole that secures the roller in relation to the holes in the clutch housing

1 - reverse gear.

16. Put a new gasket on the clutch housing collar and make sure the magnet is in place.

17. Install the main body of the gearbox on the shafts and the shaft of the sliders, and then use a metal tube to drive the ball bearing onto the input shaft while supporting the shaft on a block of hard wood.

18. Screw in and tighten the reverse shaft fixing bolt, then screw in and tighten the bolts connecting the main gearbox housing to the clutch housing.

19. Check the tightness of the input shaft ball bearing retaining plate bolts.

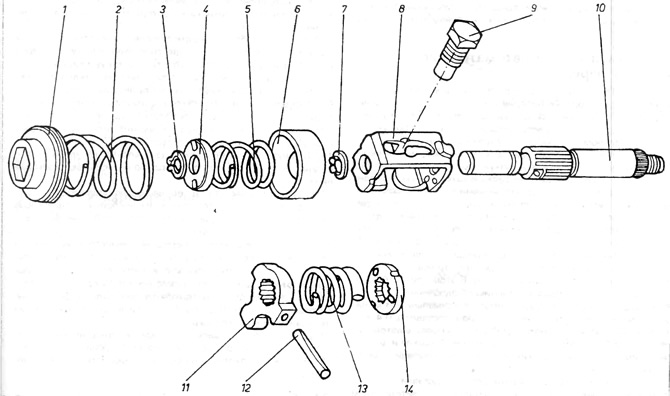

20. Install thrust washer 26, 5th speed gears on the input shaft with the phase in the direction of the bearing, and then the needle bearing 23 (pic. 6.20).

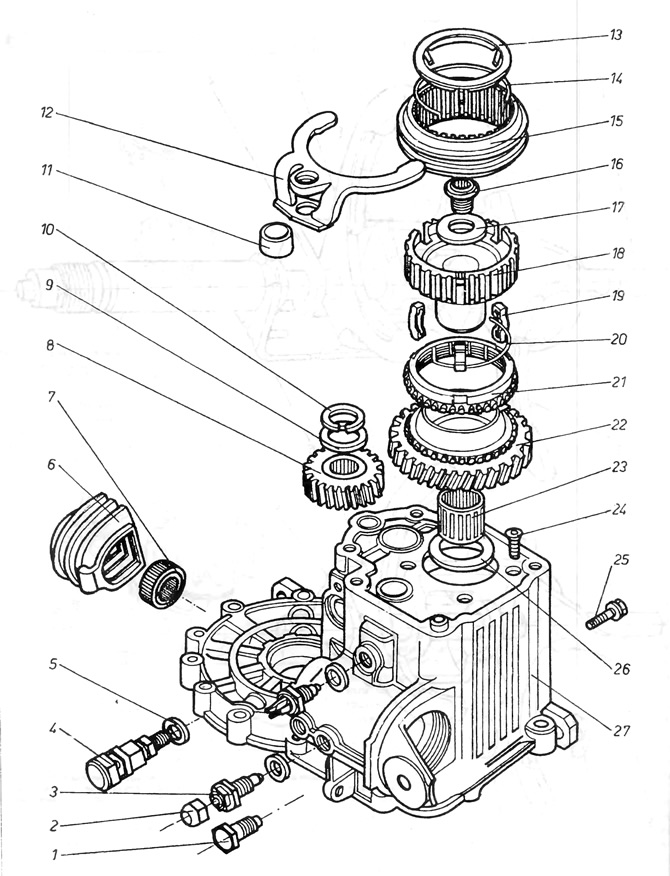

Pic. 6.20. 5th Gears 020

1 - fixing bolt of the selector shaft assembly; 2 - plug; 3 - selector shaft pawl used in four-speed gearboxes; 5 - washer; 6 - rubber casing of the selector shaft; 7 - selector shaft seal; 8 - gear wheel of the 5th gear; 9 - washer; 10 - springy ring; 11 - slider bushing; 12 - 5th speed forks; 13 - protective tin plate; 14 - spring ring; 15 - movable clutch of the synchronizer of the 5th speed; 16 - bolt securing the synchronizer assembly; 17 - washer; 18 - synchronizer hub; 14 - cracker, 20 - spring ring 21 - synchronizer ring; 22 - gear wheel of the 5th speed; 23 - needle bearing; 24 - bolts securing the ball bearing plate; 25 - bolt securing the reverse shaft; 26 - washer; 27 - the main body of the gearbox.

21. Warm up the gear of the 5th speed 8 to 100°C and press it onto the output shaft so that the notch visible on the side surface of the gear is on the side of the gearbox rear cover.

22. Install support washer 9 and a new spring ring 10 on the output shaft.

23. With the forks installed in the groove of the coupling 15, put the gear 22, the synchronizer ring 21 and the synchronizer on the main shaft, the slider sleeve 11 together with the fixing plate.

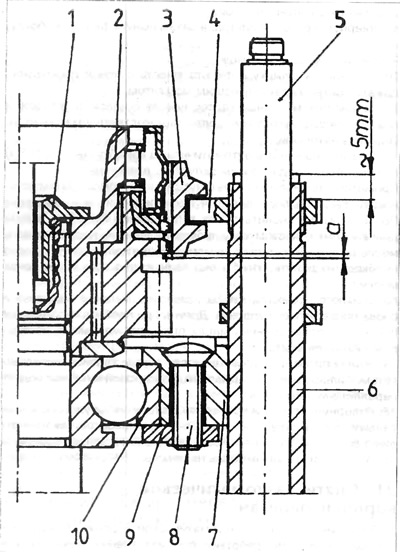

24. Without moving the slider, screw in the tube of the slider (clockwise) into forks 12 until it protrudes 5 mm above the forks. Care must be taken not to remove the slider shaft from the tube during this operation, as otherwise the sliders inside the gearbox will disintegrate and it will be necessary to remove the gearbox housing to reinstall them on the shaft.

25. Coat the thread of the fixing bolt 16 with blocking substance and screw it into the input shaft. Engage fifth gear and reverse gear through the hole in the selector shaft, then tighten the bolt with this torque.

26. Shift into neutral and insert the selector shaft assembly. For this operation, it is best to place the gearbox on its side so that the selector shaft can be lowered into place vertically. Before doing this, check whether the slots in the sliders are installed evenly (for 4 speed box) (photo 6.58 or 6.123).

27. Put on the spring and squeeze the cover of the selector shaft (using a spark plug wrench).

28. Install and squeeze the reverse light switch.

29. Screw in the fixing bolt of the selector shaft assembly.

30. Check the reliability of the inclusion of the fifth gear. Adjust if necessary by screwing or unscrewing the 5th slider tube.

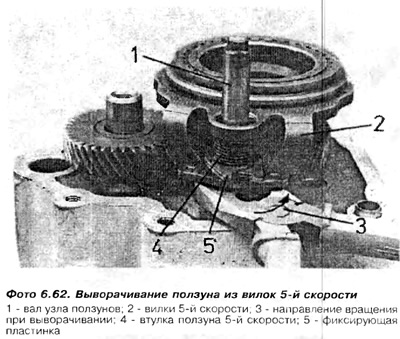

31. Support the forks with a pair of flat wrenches (19 mm and 24 mm) or another appropriate tool approx. 12 mm thick and drive in fixing plate 5 (photo 6.62).

32. Put on a new rear cover gasket and then put on the cover (with release bearing) and tighten the fixing bolts.

33. Install the left drive flange and then the spring washer, spring ring and plastic plug.

34. Lubricate the clutch pusher and insert into the input shaft.

35. The installation of the gearbox has already been completed. Now you need to turn on each gear in turn to check that they are turned on correctly.

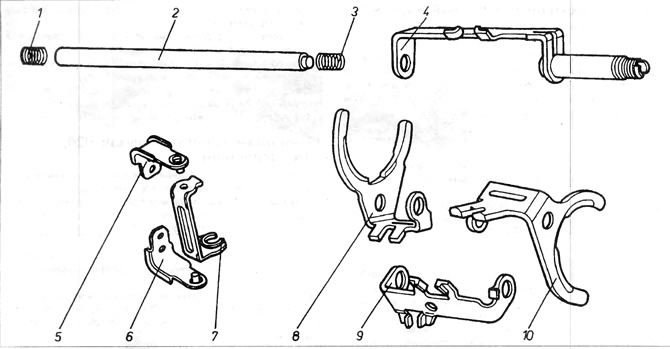

Pic. 6.17. Assembly of sliders in disassembly

1 - slider shaft spring; 2 - slider shaft; 3 - spring; 4 - slider 5th speed; 5 and 6 - support stacking forks; 7 - reverse forks; 8 - gear slider of the 1st and 2nd gears; 9 - reverse slider; 10 - gear slider of the 3rd and 4th speeds.

Pic. 6.18. Knot of sliders of a box 020, 4 and 5 speed

1 - shaft of the slider assembly; 2 - socket for engagement of reverse forks; 3 - slider 3rd and 4th speed; 4 - reverse slider; 5 - slider of the 1st and 2nd speeds; 6 - slider 5th speed; 7 - safety ring (only in 4 speed gearbox)

Pic. 6.21. 5th gear synchronizer

1 - bolt securing the synchronizer assembly; 2 - synchronizer hub; 3 - movable clutch; 4 - 5th gear forks; 5 - roller assembly of sliders; 6 - slider tube; 7 - bearing hub; 8 - rivet; 9 - plate; 10 - bearing, a = 1mm.

Pic. 6.22. Selector shaft assembly 020

1 - cover; 2 - spring; 3 - spring ring; 4 - small spring plate; 5 - internal spring; 6 - a large spring plate; 7 - spring ring; 8 - body of the distributing lever; 9 - fixing bolt, 10 - selector shaft; 11 - distributing lever; 12 - spring peg; 13 - spring; 14 - peg dog plate.

Visitor comments