2. Remove clutch release bearing and shaft.

3. To turn away and take out the switch of fires of a backing.

4. Temporarily screw two bolts into each drive flange While making the flanges stationary one by one with a rod, unscrew the fixing bolts 1 (pic. 6.2)

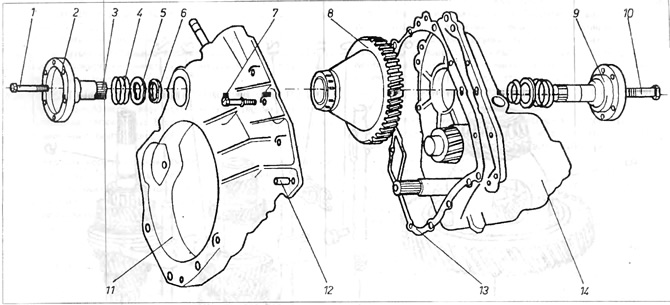

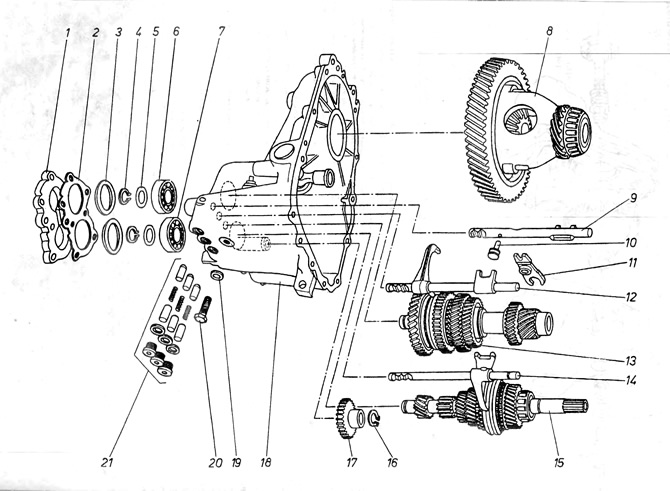

Pic. 6.2. Gearbox - 084

1 - fixing bolt; 2 - drive flange right; 3 - forklift on the drive flange; 4 - spring; 5 - support washer; 6 - conical ring; 7 bolt securing the clutch housing; 8 - main gear with differential mechanism; 9 - drive flange left; 10 - fixing bolt; 11 clutch housing; 12 - fixing pin; 13 - gasket; 14 - gearbox housing.

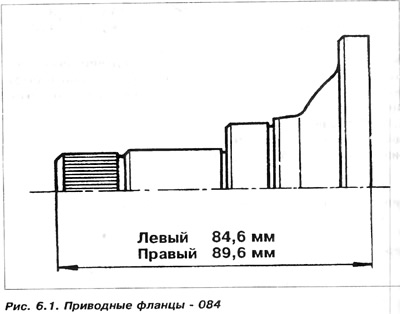

Label each flange (right and left), then remove them from the main gear. Drive flanges in various lengths (pic. 6.1).

Remove spring 4, support washer 5 and taper ring 6 from the drive flange seat 2 on the final drive housing and store them together with the respective drive flanges (fig 6.2).

5. The drive flange seals can be removed and replaced with new ones, if necessary, immediately or later after the differential mechanism has been removed.

This operation can also be performed with the gearbox installed after removing the drive flanges. Please note that the right and left seals have different sizes.

6. Loosen and remove the bolts connecting the clutch housing to the main housing. Make sure all bolts are removed from the clutch housing.

7. Support the gearbox with the clutch housing on top, and then use a wooden mallet to separate the clutch housing from the main housing, then set it aside.

8. Remove the magnet collecting sawdust from the groove on the gearbox housing.

9. Remove the differential mechanism from the gearbox.

10. Support the main gearbox housing with the back cover up.

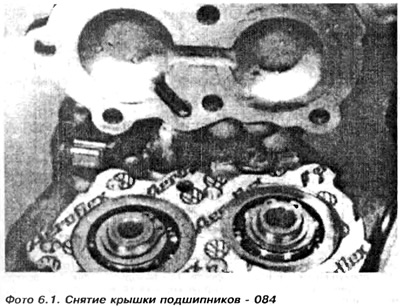

11. Unscrew and remove the bolts, as well as the rear bearing cover (photo 6.1) Locate the input and output shaft bearing spacers, and then remove them. It is not necessary to replace the spacer washers, since then it will be necessary to adjust the longitudinal clearances of the shafts during installation. Take out the gasket.

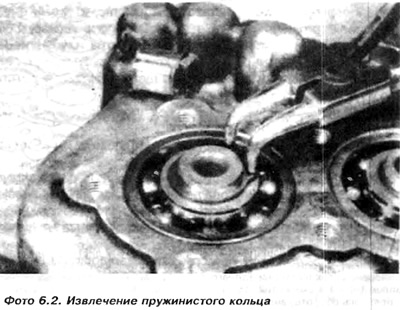

12. Using pliers, remove the spring retaining ring from the entrance hall, and then remove the small spacer (photo 6.2)

13. Check whether the selector shaft is in a free position, and then, using a hex wrench, unscrew the lock rod together with the bushing washers, springs and locking pins 21 (pic. 6.3)

Pic. 6.3. Gearbox - 084

1 - rear bearing cover; 2 - gasket; 3 - spacers; 4 - springy rings; 5 - spacers; 6 - ball bearing of the output shaft; 7 - input shaft ball bearing; 8 - differential mechanism; 9 - slider of reverse gear forks; 10 - pin of the forks of the reverse gear; 11 - reverse gear forks; 12 - slider forks of the 1st and 2nd speed; 13 - output roller; 14 - slider forks of the 3rd and 4th speeds; 15 - input roller; 16 - spring ring; 17 - reverse gear; 18 - gearbox housing; 19 - washer; 20 - bolt (rotation axis) reverse gear forks; 21 - a node of blocking elements against the simultaneous inclusion of two speeds.

14. Unscrew bolt 20 with a head for a curly screwdriver, reverse gear fork. This bolt is located next to the lock rod holes. The bolt is very tight, so you will need an impact screwdriver or chisel to remove the bolt.

15. Turn the gearbox housing and remove the slider of the reverse gear forks 9 and forks 11. The forks have cutouts at the ends, which include the king pin 10 of the slider 9 on one side and the reverse gear 17 on the other side.

16. Then you need to remove the shafts, input 15 and output 43. You can remove two shafts, simultaneously knocking them out through ball bearings 6 and 7.

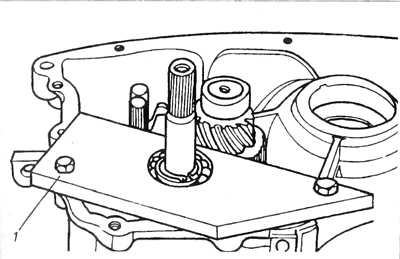

17. To take out the shafts separately, it is necessary to prepare a special backing plate and screw it to the body so as to make the input shaft stationary (pic. 6.4). Place a M16 hex nut between the shaft lever and the box body so as to block the shaft.

Pic. 6.4. Fixing plate (input shaft)

1 - fixing plate.

18. Support the gearbox with ball bearings up, and then, using a special puller, remove the input shaft bearing from the housing.

19. Remove the special support plate.

20. Using an M16 nut or a piece of wire, hold the selector shaft while bending the spring.

21. Move the input shaft away from the output shaft, and then remove it, along with the slider and the 3rd and 4th speed forks, from the gearbox. Slightly lift the reverse gear gear so that the 1st speed gear of the input shaft can pass.

22. Remove the M16 nut or piece of wire used to block the selector shaft.

23. Using pliers, remove the spring retaining ring from the end of the output shaft and the small spacer (photo 6.2).

24. Using a puller, push the output shaft out of the end bearing and simultaneously remove the slider and 1st and 2nd speed forks and reverse gear. trace. so that the shaft and reverse gear do not jam.

25. Remove the blocking rod 21 from the gearbox housing (if left).

26. Using a soft metal punch, knock out the input shaft bearing from the gearbox housing. Designate the bearing for the input and output shafts.

Visitor comments