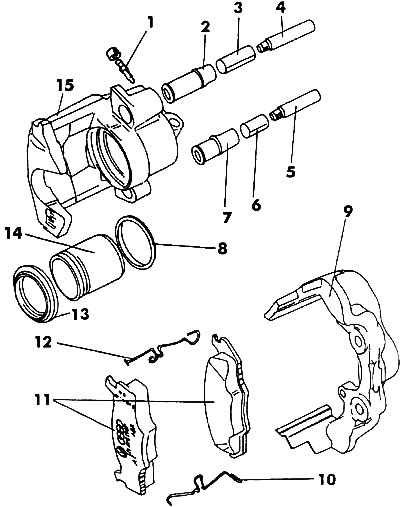

Pic. 416. Details of the brake caliper of the old type: 1 - fitting for pumping with a cap; 2 - top sleeve; 3 - upper sliding sleeve; 4 - top guide (40 Nm); 5 - bottom guide; 6 - lower sliding sleeve; 7 - lower sleeve; 8 - cuff of the cylinder; 9 - caliper bracket; 10 - lower spring; 11 - brake pads; 12 - upper spring; 13 - anther; 14 - piston; 15 - support

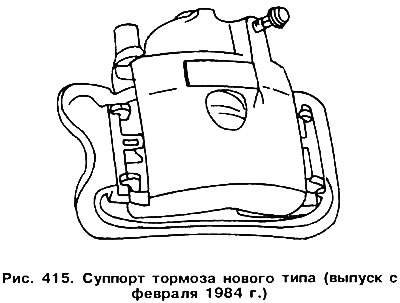

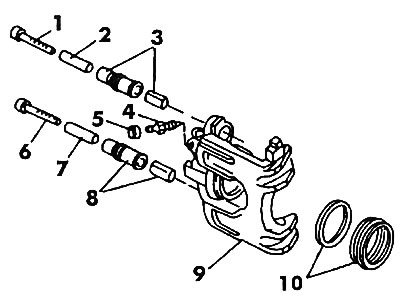

Pic. 417. New type brake caliper parts: 1, 6 - bolts (М8х45); 2, 7 - sliding bushings; 3, 8 - sets of guide bushings; 4 - fitting; 5 - cap; 9 - support; 10 - anthers

Raise the front of the car and install stands.

Remove the upper and lower springs on the old style brake. In the new type of brake mechanism, the clamping spring will come out together with the caliper bracket.

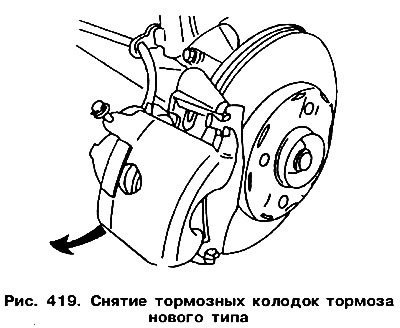

Turn away both bolts shown on fig. 418, remove the caliper. Although the mounting bolts are different in the old and new versions, the operations for removing the caliper are similar. For a new type of caliper, take its body by the lower part and pull it up in the direction of the arrow (pic. 419).

Slide the brake pads out of the guides. With a new type of caliper, the clamping springs remain in the lower as well as the upper part of the steering knuckle, and they must be removed from the sockets shown in fig. 420. Using a wooden lining, carefully push the piston into the brake cylinder. To prevent leakage of brake fluid from the reservoir with brake fluid, you need to reduce its amount in the system (for example, pumping out with a rubber bulb).

Measure the thickness of the brake pads and if they are thinner than 7mm, replace all pads.

Clean the bracket and caliper cylinder. Check for signs of leaks that would indicate a cylinder leak. In this case, it becomes necessary to repair or replace the caliper.

Installation of brake pads is carried out in the following order:

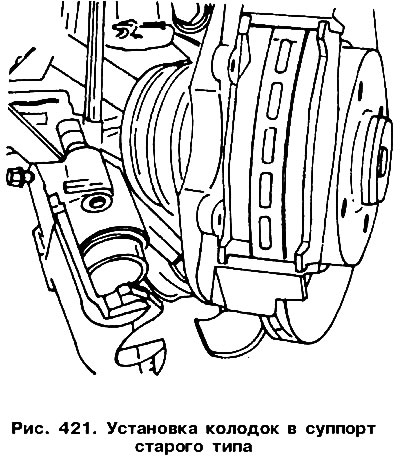

Caliper of the old type

Insert both pads into the guide brackets (pic. 421) and install the brake cylinder. Tighten the bolts to a torque of 40 Nm.

Install both springs shown in fig. 422. Follow the rest of the steps in the reverse order of disassembly.

Check and, if necessary, add brake fluid to the reservoir. Depress the brake pedal several times to bring the brake pads closer to the disc. Tighten the wheel nuts to 110 Nm.

New type caliper «Mk II» with brake pads 14 mm thick

In this case, it is necessary to place a block with a thicker lining on the outside.

Both pressure springs shown in fig. 423, install in the caliper bracket. These springs must be replaced along with the brake pads. They should take the position shown in Fig. 420. Install the caliper so that both bolts can be screwed in. Inserting the caliper too deep can cause the springs to deform.

Attach the top of the caliper to the caliper bracket, then lower down (opposite to that shown in Fig. 419).

Tighten both bolts in several stages to a torque of 25 Nm.

Carry out the rest of the operations given for the old caliper type (same for new).

Visitor comments