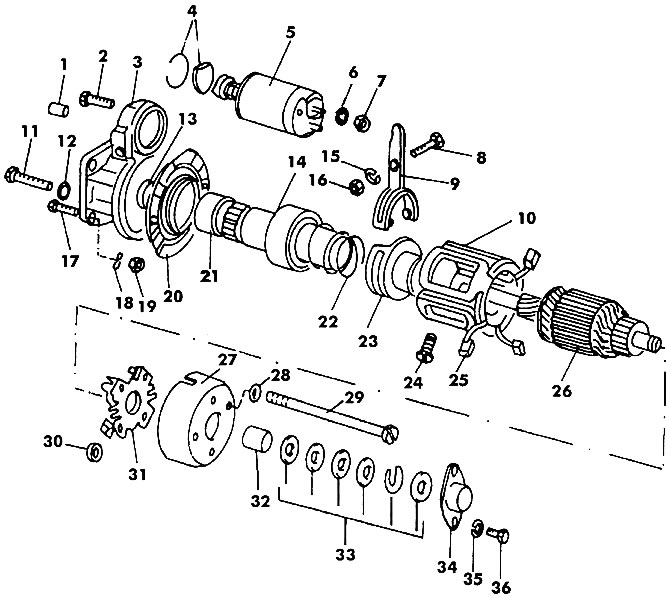

Pic. 447. Starter: 1 - thrust bearing; 2 - bolt; 3 - back cover; 4 - fork fastening details; 5 - retractor relay; b, 15, 35 - spring washers; 7 - nut M8; 8 - axis of the lever; 9 - lever; 10 - stator winding; 11 - bolt M10; 12, 28 - washers; 13 - thrust ring; 14 - overrunning clutch; 16 - nut Mb; 17 - bolt M8; 18 - retaining ring; 19 - nut M8; 20 - bearing cover; 21 - bushing; 22 - spring; 23 - sliding sleeve (absent in the 1.3 liter engine); 24 - screw on the terminal; 25 - carbon brush; 26 - anchor; 27 - collector cover; 29 - tightening bolt; 30 - spring; 31 - brush holder; 32 - sliding sleeve; 33 - set of washers; 34 - cover; 36 - bolt

Unscrew bolts 36 and remove cover 34. Unscrew tightening bolts 29.

Remove the retaining ring with a screwdriver, remove the washers from the end of the shaft and remove the starter housing with the stator windings.

Remove the carbon brushes from the brush holder and remove the brush holder. Remove the starter housing from the stator winding. Remove the bolt securing the wire lever and remove the lever.

Remove the gasket from the head, paying attention to its position.

Brushes connected to the stator winding can only be replaced together with the corresponding winding as follows:

- unscrew the screws securing the stator terminals by hitting it with a sharp copper rod, as shown in fig. 448;

- take out the terminals, as well as the windings with brushes. when removing the anchor or overrunning clutch, remove the retaining ring (arrow in fig. 449).

|  |

Remove the circlip from the groove. If necessary, deburr the end of the shaft.

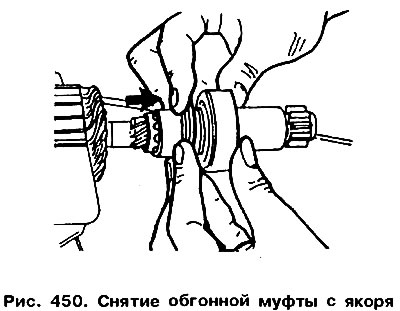

Fix the anchor in a vise and remove the overrunning clutch from the shaft (pic. 450).

All starter parts (except for the stator) rinse in gasoline and check for burnt windings on the armature, and also if the collector is scratched. Small scratches can be removed with very fine sandpaper, larger ones should be removed on a lathe. The freewheel cannot be repaired and must be replaced if damaged. The starter is assembled in the reverse order. It should be determined whether the brushes have worn out to a minimum size of 131 mm. If it is necessary to replace them, the old brushes must be crushed with tongs and the ends of the braided wires cleaned. insert into new brushes, flatten on the other side and, holding from below, solder.

When assembling the starter, the following instructions must be observed:

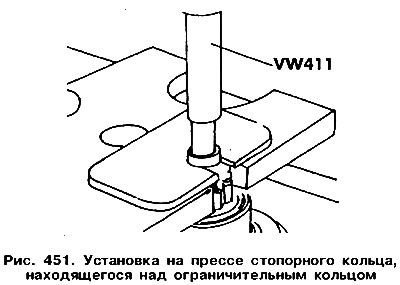

Put the one-way clutch on the shaft, install the restrictive ring and a new circlip. Place the stop ring on the press plate (pic. 451). Having correctly calculated the pressure on the armature shaft, insert the retaining ring into the restrictor.

If you need to replace the manifold bushing (you can just take it off), then before installing a new bushing, it should be held for 5 minutes in hot oil.

During the installation of the solenoid relay, attention should be paid to ensure that the pusher is correctly connected to the drive lever.

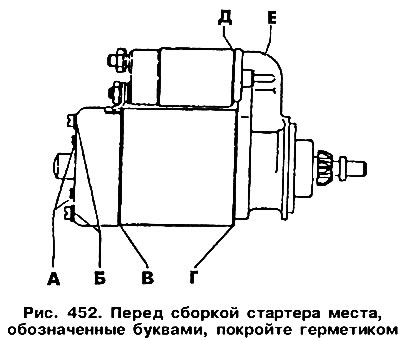

The places shown in fig. 452, coat with sealants «D3».

The axial play of the anchor should be 0.1-0.3 mm. It can be installed by changing the thickness of the shims in the starter housing and the safety C-washer.

Visitor comments