Accelerator pump performance

To perform the measurement, it is necessary to remove the carburetor: engine. Remove the carburetor cap, fill the float chamber with gasoline and reinstall the cap. Prepare a funnel and a measuring vessel,

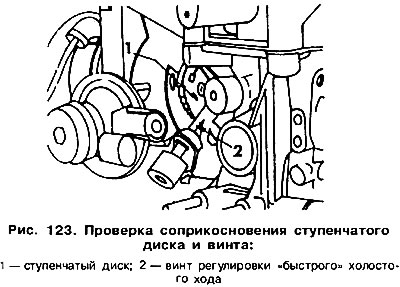

Check if the mode adjustment screw is touching «quick» idling with a stepped disk. If it touches, turn the dial (see fig. 123).

Insert the funnel into the beaker, and place the carburetor over the funnel.

Open the throttle slowly 10 times. Each opening should last at least 3 seconds.

Divide the amount of fuel collected in the beaker by 10. The result should be (1,0±0,15) cm3.

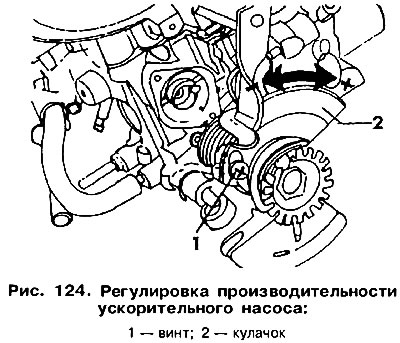

Loosen screw 1 if necessary (rice 124) and turn cam 2. By turning it in the direction «+», we increase the performance of the pump, and in the direction «-» reduce. Tighten screw 1 and lock it. Before adjusting, it is necessary to remove the fastening of the accelerator control rod from the damper shaft.

Throttle valve installation

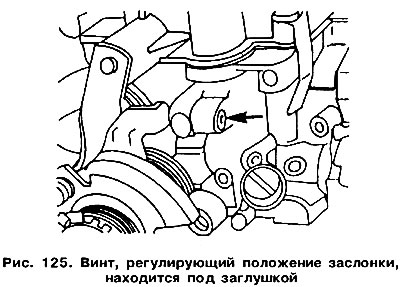

The throttle position is set at the factory and its adjusting screw is sealed to maintain this position, so do not remove the plug (arrow in fig. 125), blocking access to the screw,

But if you still have to turn the adjusting screw, it must again take a normalized position. To do this, do the following:

Remove the plug with a screwdriver.

Swing the damper and so turn the stepped disk 1 (rice 123), so that the fast idle adjusting screw does not touch the disc, Turn out the throttle setting adjusting screw until there is a gap between its end and the throttle limiting lever, Then screw in the screw until it comes into contact with the lever, To make it easier to fix this moment, it is recommended to place a piece of paper between the screw and the lever. By moving the paper up and down and simultaneously turning the screw, you can accurately determine the moment of their contact.

From this position, screw in the screw an additional 1/2 turn. Close the screw with a new plug. Adjust the mixture and idle speed.

Setting the fast idle speed

If the engine constantly stalls at idle without load, it is necessary to adjust the so-called «quick» idle move. The engine must be warm and have the initial ignition angle and idle speed correctly set.

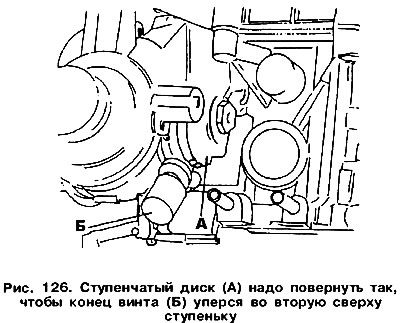

Rotate the flap and install stepped disc A (pic. 126) so that the end of the adjusting screw B fixes the second step from the top.

Start the engine without depressing the throttle control pedal. Check engine speed. If she doesn't reach (2000±100) rpm, remove the plug from screw B and adjust the speed.

Put a new cap on the screw.

Air damper installation

Data for adjusting the position of the air damper is not given, since a vacuum pump and special measuring instruments from VW are required to check it.

Idle adjustment

Idle adjustment consists of setting the engine speed, as well as adjusting the carbon monoxide content (SO) in exhaust gases. These parameters are interdependent. Therefore, the idle speed is first set, and then they begin to check and possibly adjust the composition of the combustible mixture. Before starting work on adjusting the idle speed, the following conditions must be met:

The engine must be warmed up to operating temperature. Check whether the air damper is fully open, i.e. whether the adjusting screw 2 is touching (pic. 123) with stepped disc 1, Since the air damper and disc are not interconnected in this carburetor, it may happen that after the start of movement of the air and throttle dampers, the disc will not turn. In this case, it is necessary to shake the stepped disk 1 so that it releases the end of the screw.

All electrical consumers must be turned off, this also applies to the electric fan.

Disconnect the crankcase ventilation hoses from the air filter. The end of the hose must be plugged.

The ignition must be properly adjusted.

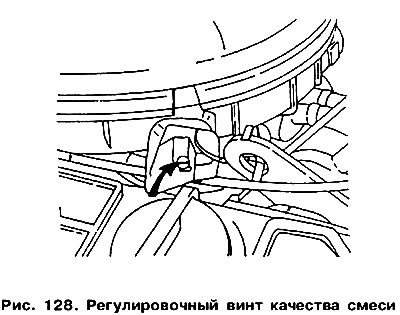

Check the idle speed with a tachometer. It must constitute (800±50) rpm If necessary, adjust it with the adjusting screw (arrow in fig. 127). Using a gas analyzer, check the CO content in the exhaust gases. It must be within (2,0±0,5) %. Otherwise, it must be corrected using the adjusting screw (arrow in fig. 128).

|  |

Connecting the crankcase ventilation hose increases the CO content in the exhaust gases. This is due to the fact that oil vapors are always present in the crankcase.

After adjustment, put the blue plug on the mixture quality adjustment screw.

Idle speed increase valve.

In order to prevent the engine speed from falling below 700 rpm under certain operating conditions, a vacuum-controlled valve located in the mixture control device is turned on. Due to this, an additional channel opens, through which an additional amount of mixture enters the carburetor, which causes an increase in the idle speed.

Checking the process of increasing idle speed, as well as the operation of the valve installed in the control device, requires special equipment and is carried out at VW service stations.

Visitor comments