Golf 1 (1974-1984, diesel)

Golf 1 (1974-1984, petrol)

Golf 2 (1984-1993, petrol)

Golf 2 (1984-1993)

Golf 3 (1991-1997)

Golf 4 (1997-2004)

Golf 5 (2003-2008)

Gasoline engine 1.3L car Volkswagen Golf 2

Removal and installation of the engine

The engine is removed from the engine compartment upwards along with the gearbox, which can later be disconnected. A lift must be used for this operation (hoist) appropriate load...

The engine is removed from the engine compartment upwards along with the gearbox, which can later be disconnected. A lift must be used for this operation (hoist) appropriate load...

Engine disassembly

Before starting work, thoroughly clean all external surfaces of the engine. Plug all openings in the engine with clean rags so that dirt does not get into them. During...

Before starting work, thoroughly clean all external surfaces of the engine. Plug all openings in the engine with clean rags so that dirt does not get into them. During...

Engine Assembly

The engine is assembled in the reverse order of disassembly. When performing these operations, follow the instructions below. Before installation, each part must be cleaned. All...

The engine is assembled in the reverse order of disassembly. When performing these operations, follow the instructions below. Before installation, each part must be cleaned. All...

Cylinder head — general information

Before disassembling and adjusting the cylinder head and timing mechanism, follow the instructions below: The camshaft is mounted in the block head in five bearings. The rear...

Before disassembling and adjusting the cylinder head and timing mechanism, follow the instructions below: The camshaft is mounted in the block head in five bearings. The rear...

Removing the cylinder head without removing the engine

The cylinder head can be removed without removing the engine from the vehicle's engine compartment. This operation is described below. The description refers to a carbureted...

The cylinder head can be removed without removing the engine from the vehicle's engine compartment. This operation is described below. The description refers to a carbureted...

Dismantling of a head of the block of cylinders

Completely disassemble the block head. Clamp the head in a vice on the bracket screwed to the exhaust manifold studs. Gradually and alternately on each side, unscrew the bolts...

Completely disassemble the block head. Clamp the head in a vice on the bracket screwed to the exhaust manifold studs. Gradually and alternately on each side, unscrew the bolts...

Cylinder head repair

Valve springs An accurate check of the valve springs requires the use of a special measuring tool. If there is none, you can do the following: Compare the removed spring with the...

Valve springs An accurate check of the valve springs requires the use of a special measuring tool. If there is none, you can do the following: Compare the removed spring with the...

Cylinder head assembly

The cylinder head is assembled in the reverse order of its disassembly, using the following recommendations. Lubricate the valve stems with clean engine oil and install them in...

The cylinder head is assembled in the reverse order of its disassembly, using the following recommendations. Lubricate the valve stems with clean engine oil and install them in...

Installation of the cylinder head

Once again clean the mating surfaces of the block head and engine block. On the mating surface of the cylinder block, install the block head gasket so that the number printed on...

Once again clean the mating surfaces of the block head and engine block. On the mating surface of the cylinder block, install the block head gasket so that the number printed on...

Checking hydraulic valve clearance compensators

Hydraulic valve clearance compensators are an important component, as serious damage to engine parts can occur if handled incorrectly. Therefore, follow these guidelines: It is...

Hydraulic valve clearance compensators are an important component, as serious damage to engine parts can occur if handled incorrectly. Therefore, follow these guidelines: It is...

Camshaft oil seal replacement

The camshaft oil seal can be replaced without removing the engine if an oil leak is noticed in the installation area. The oil seal is behind the camshaft sprocket. To remove the...

The camshaft oil seal can be replaced without removing the engine if an oil leak is noticed in the installation area. The oil seal is behind the camshaft sprocket. To remove the...

Removing pistons and connecting rods from the cylinder block

The pistons and connecting rods are removed from the cylinder block upwards with the connecting rod bearing caps and liners previously removed. Before performing these operations,...

The pistons and connecting rods are removed from the cylinder block upwards with the connecting rod bearing caps and liners previously removed. Before performing these operations,...

Measurement of cylinder diameters

To determine the degree of wear of the cylinder mirror, an inside gauge is needed. The diameter is measured in a direction parallel to the axis of the crankshaft, as well as in a...

To determine the degree of wear of the cylinder mirror, an inside gauge is needed. The diameter is measured in a direction parallel to the axis of the crankshaft, as well as in a...

Inspection of piston rings, ring grooves and connecting rods

All elements of the connecting rod and piston group must be checked, and if they are worn out, have deep scratches and other damage, they must be replaced. Checking the condition...

All elements of the connecting rod and piston group must be checked, and if they are worn out, have deep scratches and other damage, they must be replaced. Checking the condition...

Assembling the connecting rod and piston group

If the pistons have been replaced, make sure they are the same type as the old ones. Heat up the piston to 60°C (by immersing it in hot water) inspect the auxiliary rod, which is...

If the pistons have been replaced, make sure they are the same type as the old ones. Heat up the piston to 60°C (by immersing it in hot water) inspect the auxiliary rod, which is...

Installation of pistons and connecting rods in cylinders

Lubricate the cylinder mirrors liberally with engine oil. Arrange the connecting rods in the order of cylinder numbering. The lugs on the bottom head and connecting rod cap must...

Lubricate the cylinder mirrors liberally with engine oil. Arrange the connecting rods in the order of cylinder numbering. The lugs on the bottom head and connecting rod cap must...

Cylinder block — check

In case of complete disassembly of the engine, wash the cylinder block well, clean the oil channels and channels for supplying coolant. At the same time, it is necessary to pay...

In case of complete disassembly of the engine, wash the cylinder block well, clean the oil channels and channels for supplying coolant. At the same time, it is necessary to pay...

Removing the crankshaft

To remove the crankshaft, you must remove the engine from the engine compartment of the car. Next, disconnect the engine from the gearbox. When removing the gearbox, do not bend...

To remove the crankshaft, you must remove the engine from the engine compartment of the car. Next, disconnect the engine from the gearbox. When removing the gearbox, do not bend...

Checking the crankshaft

Carefully inspect the crankshaft for signs of damage, and then measure the diameter of the main and connecting rod journals. Three repair sizes are provided for regrinding the...

Carefully inspect the crankshaft for signs of damage, and then measure the diameter of the main and connecting rod journals. Three repair sizes are provided for regrinding the...

Installing the crankshaft

Clean the sockets for the main bearings in the engine block, put the bearings with an oil supply groove into the sockets so that their protrusions fall into the grooves ( see fig....

Clean the sockets for the main bearings in the engine block, put the bearings with an oil supply groove into the sockets so that their protrusions fall into the grooves ( see fig....

Removing the crankshaft seals

The front and rear crankshaft seals must be replaced each time the crankshaft is removed. Replacement requires a special tool and the special precautions described below. Both oil...

The front and rear crankshaft seals must be replaced each time the crankshaft is removed. Replacement requires a special tool and the special precautions described below. Both oil...

Installation of crankshaft seals

Installing oil seals on an engine removed from a vehicle Lubricate the seal lip and cage and carefully press it into the cover flush with the cover. Carefully put the cover with...

Installing oil seals on an engine removed from a vehicle Lubricate the seal lip and cage and carefully press it into the cover flush with the cover. Carefully put the cover with...

Flywheel replacement

On the described engines, a flywheel of a typical design is used, bolted directly"to the crankshaft flange. To remove the flywheel, block it (e.g. with a screwdriver) and loosen...

On the described engines, a flywheel of a typical design is used, bolted directly"to the crankshaft flange. To remove the flywheel, block it (e.g. with a screwdriver) and loosen...

Gas distribution mechanism — design description

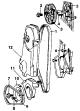

To drive the camshaft located in the cylinder head, there is a toothed belt laid on the toothed pulleys of the crankshaft and camshaft and the fluid pump shaft, see fig. 90. Pic....

To drive the camshaft located in the cylinder head, there is a toothed belt laid on the toothed pulleys of the crankshaft and camshaft and the fluid pump shaft, see fig. 90. Pic....

Toothed belt replacement

The toothed belt is under the protective cover. The belt is designed for a run of 100,000 km, unless, of course, it does not have mechanical damage by this time. In cases where...

The toothed belt is under the protective cover. The belt is designed for a run of 100,000 km, unless, of course, it does not have mechanical damage by this time. In cases where...

Checking and installing valve timing

Timing gear drive pulleys are provided with alignment marks. The position of the pulley mounted on the crankshaft should be related to the notch mark • on the V-belt pulley in...

Timing gear drive pulleys are provided with alignment marks. The position of the pulley mounted on the crankshaft should be related to the notch mark • on the V-belt pulley in...

Replacing the camshaft without removing the engine

Withdrawal camshaft on an engine installed in a car is carried out as follows: Turning the crankshaft, install the pistons so that none of them is at TDC. Remove the valve cover....

Withdrawal camshaft on an engine installed in a car is carried out as follows: Turning the crankshaft, install the pistons so that none of them is at TDC. Remove the valve cover....

This section is available on russian, bulgarian, belarusian, ukrainian, serbian, croatian, romanian, polish, slovak, hungarian

Similar sections from other manuals for VW cars:

Petrol engine 2.0L: Engine repair Volkswagen Passat B6 (2005-2010)

Power unit: Petrol engines 1.4 and 1.6 Volkswagen Polo 3 (1995-2003)

Power unit: Petrol engine 3.2L Volkswagen Touareg 1 (2002-2006)

Power unit: Petrol engine 1.4 CAVA Volkswagen Tiguan 1 (2007-2015)

Power unit: Engine repair Volkswagen Transporter T4 (1990-2003)

Diesel engines: Engine repair Volkswagen Caddy 3 (2003-2010)

Petrol engine 2.0L: Engine repair Volkswagen Passat B6 (2005-2010)

Power unit: Petrol engines 1.4 and 1.6 Volkswagen Polo 3 (1995-2003)

Power unit: Petrol engine 3.2L Volkswagen Touareg 1 (2002-2006)

Power unit: Petrol engine 1.4 CAVA Volkswagen Tiguan 1 (2007-2015)

Power unit: Engine repair Volkswagen Transporter T4 (1990-2003)

Diesel engines: Engine repair Volkswagen Caddy 3 (2003-2010)

Golf 5

Golf 4

Golf 3

Golf 2

Golf 2 (petrol)

Golf 1 (petrol)

Golf 1 (diesel)

- General information

- User manual

- Maintenance

- Troubleshooting

- Power unit

- Engine repair

- Cooling and ventilation system

- Fuel system

- Ignition system

- Transmission

- Clutch

- Mechanical gearbox

- Automatic gearbox

- Chassis

- Brake system

- Car suspension

- Steering

- Body

- Interior (internal elements)

- Exterior (external elements)

- Doors and covers

- Electrical equipment

- Power devices

- Washers and wipers

- Lighting and appliances

- Electrical circuits

- General information

- User manual

- Weekly checks

- Maintenance

- Power unit

- Petrol engines

- Diesel engines

- Cooling system

- Fuel system (petrol)

- Control system (petrol)

- Fuel system (diesel)

- Exhaust system

- Transmission

- Clutch

- Car gearbox

- Drive shafts

- Chassis

- Car suspension

- Steering

- Wheels and tires

- Brake system

- Body

- Exterior (external elements)

- Interior (internal elements)

- Ventilation and heating

- Car doors and sunroof

- Washers and glass cleaners

- Electrical equipment

- Power devices

- Lighting and appliances

- Electrical circuits

- Petrol engine

- Engine repair

- Lubrication system

- Cooling system

- Ignition system

- Diesel engine

- Engine repair

- Diesel injection system

- Pre-glow system

- Transmission

- Clutch

- Gearbox and drive shafts

- Chassis

- Steering

- Wheels and suspension

- Brake system

- Electrical equipment

- Lighting and appliances

- Electrical circuits

- General information

- Introduction to guide

- User manual

- Petrol engines 1.3 l

- Engine repair

- Lubrication system

- Cooling system

- Carburetors

- Supply system

- Ignition system

- Petrol engines 1.6/1.8 l

- Engine repair

- Supply system

- Ignition system

- Diesel engines

- Engine repair

- Lubrication system

- Cooling system

- Power and exhaust system

- Transmission

- Clutch

- 4-speed gearbox 084

- 5-speed gearbox 085

- 4-speed gearbox 020/4R

- 5-speed gearbox 020/4T

- Automatic gearbox

- Drive shafts

- Chassis

- Steering

- Car suspension

- Brake system

- Body

- Body elements

- Doors, locks and windows

- Electrical equipment

- Equipment and devices

- Power devices

- General information

- Characteristics

- Car care

- Maintenance

- Power unit

- Engine repair

- Engine 1.05/1.30

- Engine 1.60/1.80

- Cooling and lubrication system

- Power and exhaust system

- Transmission

- Clutch

- Car gearbox

- Drive shafts

- Chassis

- Brake system

- Steering

- Suspension

- Body

- Body and equipment

- Electrical equipment

- Lighting and appliances

- Electrical circuits

- General information

- Characteristics

- User manual

- Maintenance

- Power unit

- Engine adjustment

- Engine 1.1/1.3

- Engine 1.5/1.6/1.8

- Engine electrical equipment

- Cooling system

- Fuel system

- Transmission

- Clutch and manual gearbox

- Automatic gearbox

- Chassis

- Steering

- Front suspension

- Rear suspension

- Brake system

- Electrical equipment

- Lighting and appliances

- Electrical circuits

- Body

- Body and equipment

- Optional equipment

- General information

- Specifications

- Maintenance

- Power unit

- Engine repair

- Exhaust and turbocharger

- Cooling system

- Fuel system

- Fuel injection system

- Transmission

- Clutch and drive shafts

- Car gearbox

- Chassis

- Suspension and wheels

- Steering

- Brake system

- Wheels and tires

- Body

- Heating and ventilation

- Exterior (external elements)

- Interior (internal elements)

- Doors and windows

- Electrical equipment

- Equipment and devices

- Lighting system

- Power devices

- Electrical circuits

VWmanual.ru © 2016-2024 | Mobile version | News and articles | Sitemap: EN BG BY UA RS HR RO PL SK HU | Write message | Site search

Passat B2 • Passat B3 • Passat B4 • Passat B5 • Passat B6 • Golf 1, diesel • Golf 1, petrol • Golf 2, petrol • Golf 2 • Golf 3 • Golf 4 • Golf 5 • Polo 3 • Polo 4 • Touareg 1 • Tiguan 1 • Sharan 1 • Transporter T3 • Transporter T4 • Beetle • Caddy 3 •

Passat B2 • Passat B3 • Passat B4 • Passat B5 • Passat B6 • Golf 1, diesel • Golf 1, petrol • Golf 2, petrol • Golf 2 • Golf 3 • Golf 4 • Golf 5 • Polo 3 • Polo 4 • Touareg 1 • Tiguan 1 • Sharan 1 • Transporter T3 • Transporter T4 • Beetle • Caddy 3 •