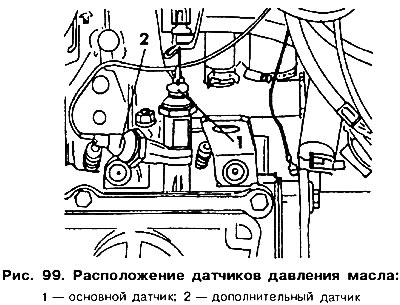

1) the main sensor with a brown body, which is triggered at P=0.3 kg/cm2 (electrical wires black and blue);

2) additional sensor with black body Р=1.4 kg/cm2, yellow electric wires. The control lamp lights up while the engine is idling, when the oil pressure drops below 0.15-0.45 kg/cm2. The indicator lamp will also light up if the pressure falls below 1.6 kg/cm2 at a speed exceeding 2150 rpm, in which case the buzzer will sound. Both sensors are located between the spark plugs at the location shown in fig. 99. The oil pressure in the system is measured using a manometer, which must be equipped with a special fitting for connecting the device instead of the oil pressure sensor. Both sensors should be checked, but the main condition for the checks described below is the presence of a pressure gauge, shown in fig. 100 or similar with a sufficient accuracy class.

Remove the wire terminal from the oil pressure sensor and unscrew the sensor from the engine block head. The sensor is located next to the socket of one of the spark plugs.

Screw the sensor into the pressure gauge and connect the blue wire 1 to it (pic. 100).

Instead of the sensor, screw a pressure gauge into the head of the block. control lamp or electric «probe» 2 connect wire 1 with an additional battery terminal.

Brown wire 3 short to «mass». Turn on the ignition. The control lamp should light up. If it doesn't, replace the sensor or lamp.

Start the engine and let it idle. Check if the control lamp goes out under pressure (0,15-0,45) kg/cm. If it does not go out, replace the sensor.

From sensor 1 (pic. 99) disconnect wire and connect to sensor 2 (to black wire).

Increase engine speed. When it reaches 2000 rpm and the oil temperature is 80°C, the pressure gauge should show an oil pressure of 2 kg/cm2. Otherwise, the oil pump must be replaced (if the amount of oil in the oil pan is sufficient).

Visitor comments