Thanks to the use of electronic circuits, a large amount of data is used to control the fuel injection system, which comes from sensors.

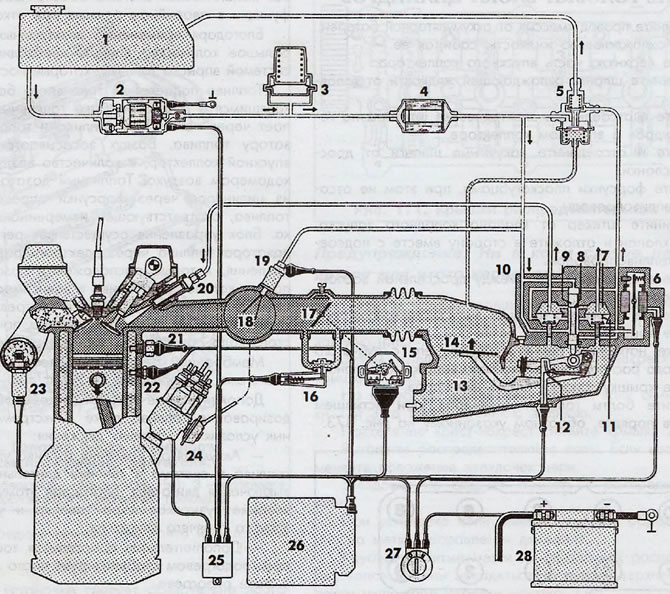

Fuel is supplied from fuel tank 1 (pic. 174) located in the fuel tank by the fuel pump and flows through the fuel accumulator and the fuel filter to the fuel dispenser. Air is drawn in by the engine through the intake manifold and the amount of air is measured by the air mass meter. The fuel dispenser supplies each of the cylinders through the nozzles with a certain amount of fuel corresponding to the measured amount of air. The control unit regulates the operation of the fuel dispenser through an electro-hydraulic pressure regulator, which is located in the dispenser and regulates the supply of fuel depending on the operating mode of the engine: when starting and warming up, during acceleration, it turns off the fuel supply in the forced idle mode at a speed of more than 1500 rpm min.

Pic. 174. Scheme of the injection system «KE-Jetronic»: 1 - fuel tank; 2 - fuel pump with electric drive; 3 - fuel pressure accumulator; 4 - fuel filter; 5 - fuel pressure regulator in the system; 6 - electro-hydraulic pressure regulator; 7 - upper chamber; 8 - control (working) spool edge; 9 - control spool; 10 - fuel dispenser; 11 - lower chamber; 12 - potentiometer; 13 - air meter; 14 - pressure disk (rotameter); 15 - throttle position sensor; 16 - valve for additional air supply; 17 - throttle valve; 18 - inlet pipe; 19 - starting nozzle; 20 - fuel injector; 21 - thermal time relay; 22 - engine temperature sensor; 23 - oxygen content sensor; 24 - sensor-distributor ignition; 25 - relay for turning on the fuel pump; 26 - electronic control unit; 27 - ignition switch; 28 - battery

Membrane pressure regulator regulates the pressure in the system within 5.2-5.9 kg/cm2.

Additional system sensors ensure accurate fuel metering even under extreme temperature and driving conditions:

- The fuel pressure accumulator maintains fuel pressure in the system for a long time after the engine has been switched off. This eliminates the formation of fuel vapor bubbles and improves starting conditions for a hot engine.

- An additional electrically heated throttle valve stabilizes the engine speed during the warm-up phase.

- The additional fuel supply valve ensures the enrichment of the working mixture in the engine warm-up phase.

- A thermal start injector injects additional fuel into the intake manifold during engine start to make the engine easier to start.

Difficulties when starting a hot engine with the KE-Jetronic system

Since March 1986, on vehicles equipped with KE-Jetronic systems, a servo radiator fan control system has been installed. At a high temperature in the engine compartment, after the engine is turned off, the time relay turns on the radiator fan for a certain time. This cools the injectors and fuel injection pipes and makes it easier to start a hot engine.

Visitor comments