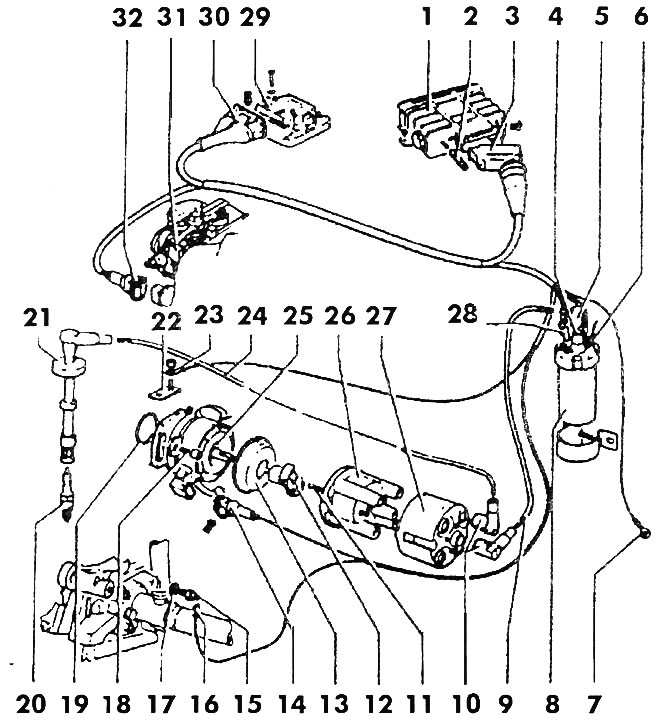

Pic. 179. Elements of the electronic ignition system VEZ: 1 - control unit; 2 - air pipeline; 3 - plug; terminal; 5 - tip; 6 - terminal 15 (+); 7 - mass cable; 8 - ignition coil; 9 - cable; 10 - tip; 11 - carbon contact; 12 - slider; 13 - protective cap; 14 - plug; 15 - temperature sensor; 16 - plug; 17 - gasket; 18 - fixing screw; 19 - sealing ring; 20 - spark plug; 21 - tip; 22 - plate; 23 - mass cable; 24 - cable; 25 - ignition distributor; 26 - cover; 27 - tip; 28 - terminal 1 (-); 29 - switch (TSZ-H); 30 - plug; 31 - throttle position sensor; 32 - plug

In the parametric control scheme of this ignition system, the optimal ignition timing is determined depending on the current engine operating mode. Control parameters are engine speed, engine temperature, intake air temperature and engine load (intake manifold vacuum, throttle position). The engine load degree refers to the current engine load, for example, there is a difference in engine operation at 4000 rpm or when the vehicle is uphill or downhill.

Along with these parameters, the knock sensor also affects the generation of the ignition moment. The knock sensor is located on the engine block and is electrically connected. wire with the control unit of the VEZ or Digifant system.

Without information about the engine speed, load level, etc., deterioration in driving performance, such as a reduction in engine power, may occur. It is also possible to increase fuel consumption. Serious engine failure should not be feared if the defect is eliminated at the earliest opportunity.

Attention! When working on the VEZ ignition system, strict safety precautions must be observed to avoid electrical shock and damage to the ignition system.

Visitor comments