Mark each connecting rod-piston pair according to the number of the cylinder from which they will be removed. This is best done with paint, applying cylinder numbers to the piston bottoms (pic. 200). Complete the numbers with an arrow pointing towards the front of the engine. The orientation of the parts can also be determined from the valve recesses.

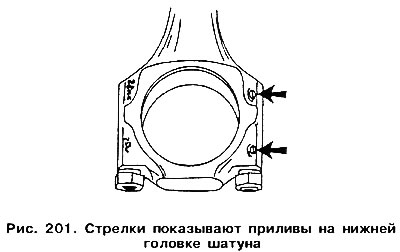

When removing the piston with the connecting rod, remember the position of the connecting rod cap. Immediately after removal, it is recommended to mark both the cover and the lower head of the connecting rod, applying the cylinder number on one side (see fig. 65). The cap and bottom end of the connecting rod are fitted with lugs at the factory (pic. 201), which, after assembly, must be aligned on the side of the intermediate shaft.

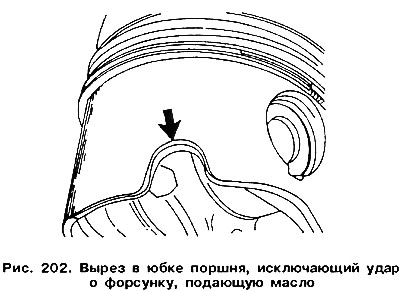

Turbocharged engine pistons have a cutout on one side of the skirt. Due to this, it is impossible for the piston to hit the nozzle for supplying oil to the BDC. When installing the piston, the cutout must be on the side of the nozzle (pic. 202).

Either deformable connecting rod bolts with a thread length of 25 mm or non-deformable connecting rod bolts with a thread length of 15 mm can be used. Deformable connecting rod bolts cannot be reused when assembling the connecting rod caps. Turbocharged engines use only deformable connecting rod bolts.

In engines with hydraulic pushers, pistons of groups II and III have a chamfer of 15°. If new pistons are installed, they must have the specified chamfers. Mark the liners of each connecting rod. To distinguish between the top and bottom liner, you can mark them with paint on the convex part. After removing the connecting rod caps and bearings, lift the pistons with the connecting rods up out of the cylinder block. If necessary, remove the upper shoulder from the surface of the cylinder mirror. Remove retaining rings and remove piston pin. The indentation next to the finger hole allows the use of a sharp object (awl), which hooks the retaining ring, as shown in rice. 68.

Remove the piston rings from the pistons one by one using a piston ring pliers (see fig. 69). If the rings are to be used again, they must be marked. If special forceps are not available, steel strips can be used, which are placed under the rings around the circumference through 120°. One of the steel strips is placed under the locks of the rings so as not to spoil the cylinder mirror (pic. 203).

Visitor comments