Lubricate the valve stems well with engine oil and insert them into the guide bushings.

Insert the lower plates of the valve springs, using special tongs.

Install the valve stem seals on the valve stem. For installation, you can use the special tool shown in rice. 59, in the following way:

- on the protruding valve stem, put on the plastic sleeve included in the tool kit;

- lubricate the valve stem cap 2 and put it on the tool bushing 3. Bring the tool to the cap and carefully put it on the valve stem.

Warning. Attempting to install the cap without using a special tool may result in damage to it, resulting in significant oil consumption.

We remind you that if the valves were previously lapped, they must be installed in their original places, otherwise their working chamfers will not match.

Reinstall the inner and outer springs (unless they are replaced). When replacing valve springs in an engine with hydraulic tappets, note that they were shorter.

Install the upper spring plate and install the spring compressor. When, after compression of the spring, the end of the rod appears above the plate, insert both crackers into the groove with tongs and slowly loosen the compression of the spring. Before this, you should check whether the crackers used previously are suitable for new valves. They must match the valve shown in fig. 190.

Use a plastic mallet to hit the end of the valve stem several times. If the studs were incorrectly installed, they should fall out of the grooves. For insurance, cover the rod with a rag.

Install the pushers in their original places according to their marks (see fig. 43) and corresponding shims.

Lubricate the camshaft journals and bearings with engine oil. Install the shaft so that both lobes of the cams above the valves of the first cylinder are directed upwards.

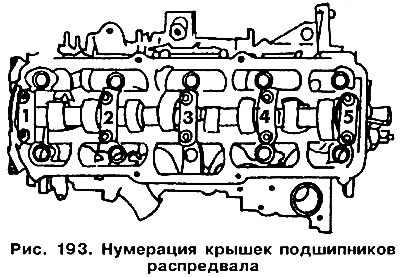

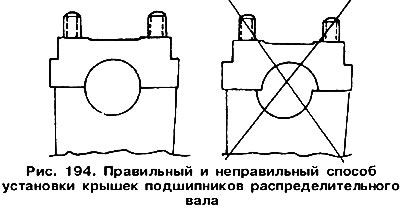

Install bearing caps Nq 1, 3 and 5 (pic. 193) and lightly tighten them with nuts. Since the covers cannot be interchanged, you should check that they are installed correctly (pic. 194).

|  |

Tighten the cap nuts gradually «criss-cross», and then tighten to 20 Nm.

Take the camshaft oil seal and determine which side the working edge is on. After installation, it should be directed outward. Lightly lubricate the seal lip and where it contacts the shaft. Install the stuffing box on the shaft neck using a nozzle of a suitable diameter. The gland must be installed flush with the end face of the block head. The oil seal can be installed in another way, as well as the front crankshaft oil seal.

Install the toothed pulley (don't forget the pin) and tighten its mounting bolts. Block the toothed pulley (like an old toothed belt) and tighten the bolts to 45 Nm.

Install intake and exhaust manifolds (using new gaskets).

Screw in the nozzles. Install other auxiliary units and parts of the block head.

Visitor comments