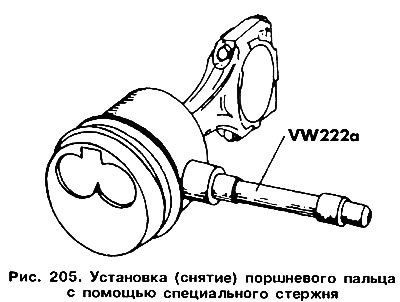

Insert the piston pin by hand into the heated piston and connecting rod head using a rod (pic. 205).

When assembling the piston and connecting rod, the following recommendations must be followed:

- arrow on the bottom of the piston (applied with paint, or in a new piston - knocked out) must be directed towards the front of the engine;

- tides on the lower head and connecting rod cap (see fig. 201) must be on the side of the intermediate shaft.

The cylinder number marks on the bottom head and connecting rod cap must match (see fig. 65).

Insert circlips on both sides of the piston pin and check whether they are firmly seated in the grooves.

Check if the assembled piston rotates easily relative to the piston pin.

With special pliers for removing and installing piston rings or the already mentioned steel strips (see fig. 203) insert the rings into the grooves under the rings. When the ring is above the groove, the steel plates should be removed, allowing it to enter the groove. Before installing the piston rings, it is necessary to pay attention to the shape of their section so as not to confuse the rings in places. In addition, both compression rings are embossed on one side «TOR» or «OBEN», which should face the piston crown.

Pistons with rings installed in them must be laid on a clean surface and covered with a lint-free material so that dirt does not get on them.

Visitor comments