Copiously lubricate the surface of the cylinder mirrors with clean engine oil.

Install the connecting rods complete with pistons in the cylinder block according to the cylinder numbering. The lugs on the lower head and the connecting rod cap must be installed from the side of the intermediate shaft.

The arrows on the piston crowns must point towards the front of the engine.

Install the piston ring locks after 120°. On rice. 199 shows how the ring locks should be installed relative to the axis of the piston pin.

Place the piston rings in the cage as shown in rice. 78, and push the rings into the grooves.

Before inserting the pistons into the cylinders, check once again whether the piston pin is locked on both sides. It may happen that after installing one retaining ring, you forgot to put the second one. Turn the crankshaft so that the two cranks are at BDC.

Insert the connecting rod into the bore of the cylinder from above. Before doing this, wrap the lower head of the connecting rod with polyethylene so as not to damage the cylinder mirror. The cylinder block should be laid on its side to facilitate installation of the connecting rod bearing caps. The connecting rod bushing should already be installed in the bottom end of the connecting rod, so that the lug of the bushing is aligned with the groove in the connecting rod head.

Insert the piston into the cylinder so that the rings enter the cylinder and the lower head is installed on the crankshaft journal.

Insert the second part of the bushing into the connecting rod bearing cap and lubricate well with engine oil. Put the cover on the connecting rod bolts and lightly tap it, having previously removed the protective material from the bolts. Check again that the lugs on the bottom head and connecting rod cap match (see fig. 201).

Lubricate the fittings of the nuts on the connecting rod cap.

The connecting rod bolts are tightened depending on the types of bolts installed:

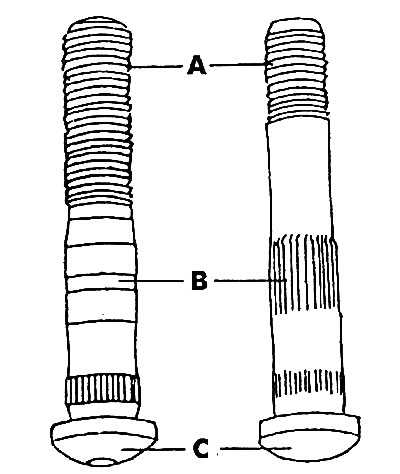

- if old design bolts are used, shown on the right side in fig. 207, then tighten the new nuts with a torque of 50 Nm;

- if new design bolts are used, shown on the left side in fig. 207, then the new nuts are tightened with a torque of 3 Nm, and then they are still tightened but half a turn.

Pic. 207. Connecting rod bearing cap bolts (on the left is the new deformable, and on the right is the old normal): A - a new bolt M8x1.25 mm or an old bolt M9x1.25; B - smooth surface (new bolt) or with gear (old bolt); C - conical head (new bolt) or rounded (old bolt)

After installing each connecting rod, rotate the crankshaft several times to check if anything is preventing its rotation.

Recheck the orientation of all connecting rods and correct installation of the pistons. In turbocharged engines, in addition, check whether the cutouts in the piston skirts are located on the side of the nozzles that spray oil.

Measure the clearance between the side surface of the connecting rod and the stop surface of the connecting rod journal of the shaft (see fig. 79), which is equal to the value of the axial play of the shaft and should not exceed 0.37 mm.

If the clearance is greater than specified, replace the connecting rods. Put on short pieces of rubber or plastic tubes on connecting rod bolts to prevent possible damage to the surface of the cylinder mirror.

Visitor comments