If it is necessary to replace the ring gear of the final drive gear, it is necessary to drill out the rivets with a 12 mm drill. This is not difficult, since the heads of the rivets have a recess in the middle (see fig. 333). After removing the heads, the rivets should be knocked out.

Heat the ring gear to 100°C and put it on the differential case. As a guide, use two bolts screwed into the body from opposite sides. For installation, use new special bolts, washers and nuts (this kit is marked in the catalog with the number 171498088). Nuts and bolts are tightened with a torque of 70 Nm.

If only the differential gears were replaced without removing the ring gear, the sawn off rivets should be replaced with two bolts.

Insert pinion gears with washers. Carefully install the satellite shaft.

Through the holes, insert the side gears so that they engage with the satellites.

Install the axle drive shafts and select the thickness of the circlips as described below:

- Advance the flange of the axle drive shaft to the axis of the satellites and move the side gear to the housing wall.

- Insert the retaining ring and check if it is pinched; if pinched, replace with a thinner one.

- Similarly, select the retaining ring for the second side gear of the wheel. Installation of the main gear is carried out in the reverse order of disassembly. The main gear must be installed before installing the axle drive shafts.

Assembly of the gearbox housing. Assembly is carried out in the reverse order to dismantling. Follow these guidelines:

- Make sure the differential housing bearings are fully engaged in the gearbox housing. Tighten the nuts of the three bolts to a torque of 15 Nm.

- Check if the reverse gear shaft is in the correct position.

- The upper part of the gearbox housing will lay; on the bottom and a rod of suitable diameter (or special - 30-23) press the ball bearing and crankcase onto the shaft. Don't forget to install the shim.

- Bolts connecting both parts of the crankcase, tighten with a torque of 25 Nm. Two short bolts are provided to install the shift rod.

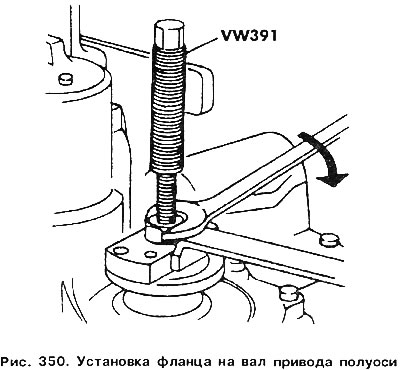

When installing the drive shaft flanges, use the tool (pic. 350). Place a lock washer on the shaft and install it into the groove using a pipe of suitable I diameter. Under the flange, install the parts shown in rice. 341.

When installing the clutch fork, pay attention not to the fact that the bent ends of the return spring rest against the crankcase wall, but its central part captures the fork Install both retaining rings.

Visitor comments