Check the condition of the synchronizer blocking ring and install the synchronizer in the manner described here.

Put spring washer 12 on the shaft (see fig. 340) ledge towards the bearing cap. Fit the 10th gear with a well lubricated needle bearing.

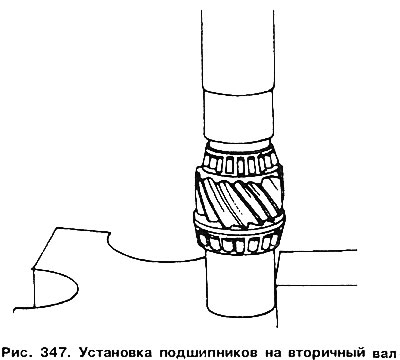

Heat the hub of the synchronizer of I/II gears with ring 9 to 120°C and install it on the shaft using a piece of pipe.

Slide the inner race of the needle bearing onto the shaft until it stops against the gear.

Put the 2nd gear on the needle bearing.

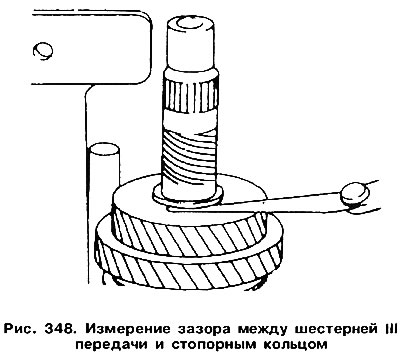

Heat the 3rd gear gear and install it on the shaft so that its ledge is directed towards the 2nd gear gear. Insert the circlip into the groove.

Measure the clearance between the 3rd gear gear and the circlip (pic. 348). The gap should be as small as possible and be in the range of 0-0.20 mm. Retaining rings are available in various thicknesses ranging from 2.5 to 3.0 mm.

Install 4th gear 3 (see fig. 340) with the ledge pointing upwards, and install a new retaining ring 2. As mentioned earlier, the limiter 1 may be missing.

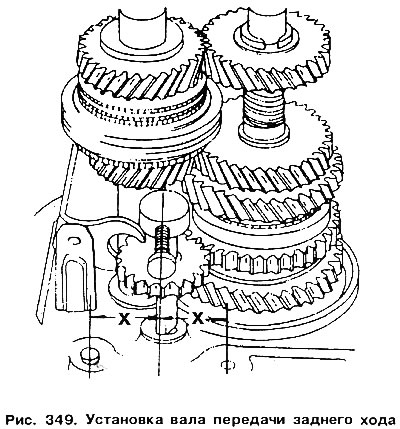

Screw the bolt into the threaded hole of the reverse gear shaft. Insert the shaft into the hole in the crankcase and position it so that the head of the bolt points to a point equidistant from both holes for the crankcase mounting bolts (dimensions «X» both sides must be the same - see fig. 349). In this position, press the shaft all the way into the bearing cover.

Visitor comments