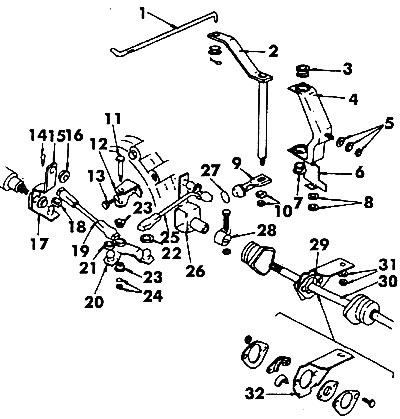

Pic. 355. Gear selection mechanism: 1 - thrust; 2 - gear selection rod; 3 - bushing; 4 - bracket for the gearshift rod; 5 - nut and washers; 6 - plate; 7 - bushing; 8, 10, 24, 31 - nuts and washers; 9 - gear selection rod; 11 - axis; 12 - angle arm bracket; 13 - bolt; 14 - hairpin; 15 - hinge; 16, 18, 21, 22 - rubber bushings; 17 - bracket; 19 - front thrust; 20, 26 - backstage; 23 - sliding sleeve; 25 - rear gear shift rod; 27 - gasket; 28 - clamp; 29 - gear lever bracket; 30 - gear selection rod; 32 - bracket plate

The rod 1 connecting the gear selection rod 2 with the bracket 17 has differently curved ends. The end of the rod that has the designation must be attached to the bracket 17. The front and rear selector rods can only be removed when the clips from the plastic tips have been removed with a screwdriver.

The shift lever can only be mounted on the stem in one position.

Lubricate all hinges and sliding surfaces with molybdenum disulphide grease when mounting the levers.

The selection mechanism is adjusted as follows:

- Set the gear selector to the neutral position.

- Check if the holes in the flange of the gear selector pivot housing are aligned (arrows in fig. 356) with holes in the hinge body. The threaded holes must be in the middle of the elongated holes. If not, then you need to unscrew the bolts and rearrange the hinge flange.

- Loosen the selector rod clutch nut (pic. 357). The stem should now move easily.

Pull off the long rubber boot and slide it along the stem. Sometimes additional loosening of the bolts securing the pivot housing plate is necessary.

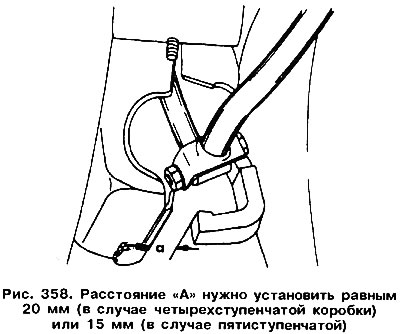

Prepare a strip of sheet metal 20 mm wide (size «A» in fig. 358) and put it in the place shown in the picture. In this position, tighten the stem coupling nut.

Check if all gears shift easily.

Visitor comments