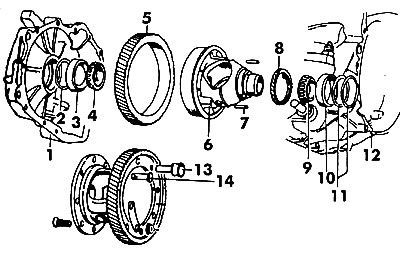

Pic. 331. Main gear scheme: 1 - gearbox housing; 2, 11 - shims; 3, 10 - outer races of bearings; 4, 9 - tapered bearings; 5 - ring gear of the driven gear of the main gear; 6 - differential case; 7 - locking pin; 8 - worm wheel of the speedometer drive; 12 - gearbox housing from the clutch side; 13, 14 - rivets

Knock out locking pins of satellites. In some versions with a riveted toothed rim, it is necessary to clamp the body in a vice and cut off the heads of the rivets 13 that fix the pin of the satellites (pic. 332). During assembly, the rivets should be replaced with bolts and nuts.

Remove the differential gears as well as the plastic cage. If the spherical nuts have no thread damage, they should not be removed from the side gears.

Bearings can be removed with a two-arm puller.

Remove the worm gear if necessary.

The ring gear of the driven gear of the final drive can either be pressed onto the differential housing or riveted to it (see fig. 331). In case of replacing a riveted gear, remove the rivets by drilling out the heads with a 12 mm drill (pic. 333), and then knock out the rivet pins. Separate the ring gear from the body, having previously cleaned it of metal filings.

If the ring gear is pressed in, it is necessary to heat the differential case to 120°C before removing it.

The differential assembly is carried out in the reverse order according to the following recommendations:

Starting assembly, put both side gears and a plastic clip into the differential case.

If the nuts of the drive shaft mounting bolts must be replaced (e.g. due to a broken thread), push them out or knock them out from the outside, and put new nuts in their place. Check that the nuts are well attached to the gears around the entire circuit (see fig. 307).

Insert both drive shafts into the side gears. Insert the satellite into the hole and turn it 180\ Then insert the second satellite and install it opposite the first one. After installing the holes of the satellites on the same axis, install the pin of the satellites. Fix the paleL with two pins. Lubricate all parts liberally.

If the ring gear of the driven gear is structurally pressed onto the differential case, then to install it, do the following:

Clean the mating surface on the differential housing with a wire brush (but not sandpaper), apply VW fixing compound on it «D6».

Heat the ring gear to 150°C and quickly insert the differential housing into it (see fig. 308). After installation, hold the pressure of the press for 1-2 minutes until the parts have cooled. The whole operation must be carried out as quickly as possible, without delay.

If the ring gear was riveted to the differential case, you need to use special bolts that are installed with washers instead of rivets. Install the gear ring on the differential case and screw it with bolts with fixing washers and nuts.

Attention! The ring gear can be replaced without simultaneously replacing the output shaft in the gearbox housing. However, you need to pay attention to the fact that the ring gear is marked (number 3 or its absence). The new ring gear must have the same markings as the removed one. An unmarked ring gear is designed for an output shaft that does not have a groove.

Fix the differential housing in a vise, tighten the bolts in turn, diagonally, to a torque of 70 Nm.

Worm gear and bearing can be pressed together. In this case, it is necessary to securely support the body. The bearing preload is adjusted in the same way as in the case of a four-speed gearbox.

Visitor comments