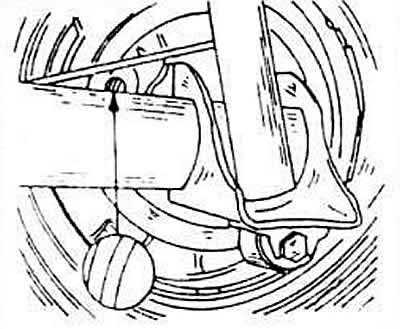

Plugs are inserted on the back of the brake pads, after removing which you can check the thickness of the brake linings. The figure shows where the control inspection hole is located. Light it with a flashlight, if the lining is worn out and its thickness is approximately 265 mm, you need to replace the pads in the kit, i.e. on both wheels.

Raise the rear of the vehicle and place it on jack stands.

Fasten the front wheels (bricks).

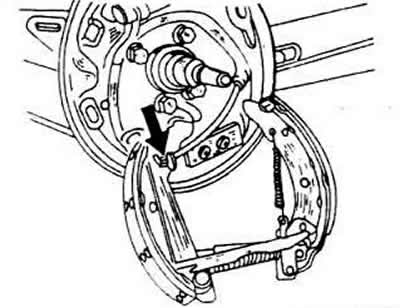

The self-adjusting brake adjuster must be disconnected as the brake pads may be hanging on the drum. To do this, insert a screwdriver into the drum through the threaded holes, find the adjusting wedge and slide it up. The adjuster sits on the top left side of the drum.

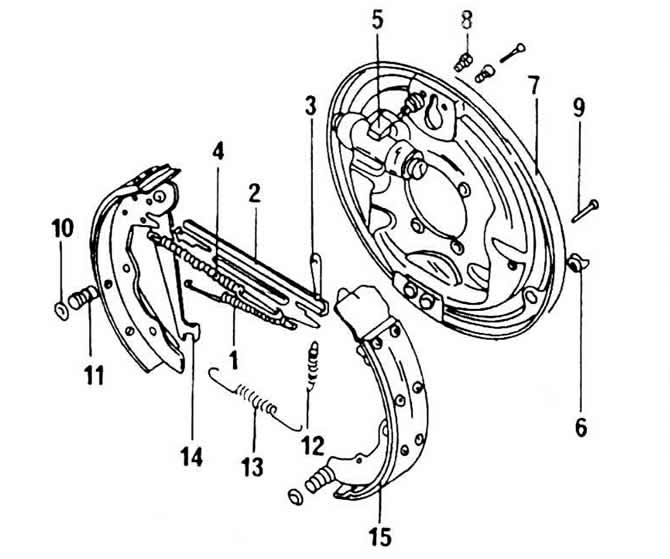

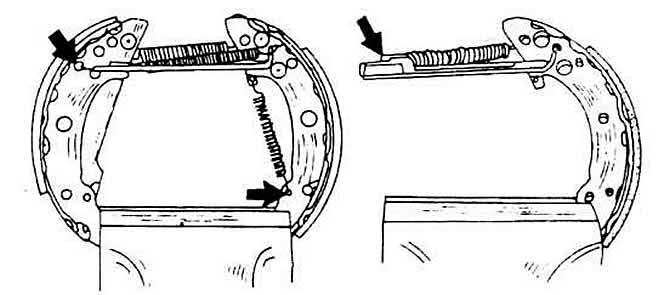

1 - upper brake pad return spring

2 - pressure piece placed between the pads

3 - adjusting wedge

4 - reverse spring

5 - wheel brake cylinder

6 - plug

7 - brake base plate

8 - hexagon socket screw

9 - anchor pin brake pads

10 - spring seat

11 - compression spring

12 - reverse adjustment spring

13 - lower brake pad return spring

14 - hand brake lever

15 - brake pads

Carefully knock off the hub grease cap using a screwdriver or special tool.

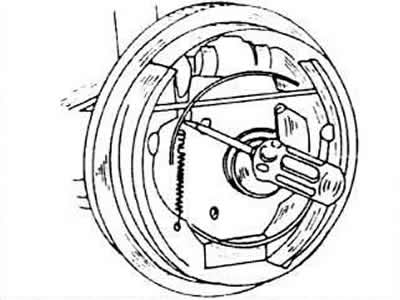

Remove the brake drum. If it should sit rigidly, then once again squeeze the adjusting wedge up with a screwdriver. The brake drum has been removed to better demonstrate the operation.

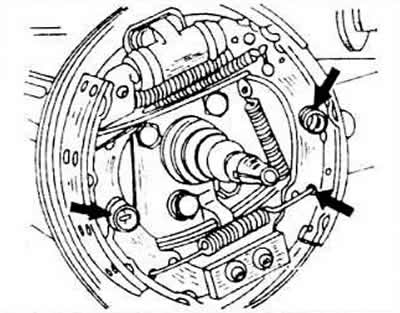

On the reverse side, press the anchor pins with your finger and grab the spring disc from the outside of the pad with tongs (top arrows), push inward, and then turn until the pin head can be guided through the spring disc. Remove the spring disc, spring and pin. Perform this operation on both pads.

Take the block from the bottom side with your hand and, lifting it, remove it from the support. Unhook the released return spring.

Tilt both brake shoes down and unhook the handbrake cable from the shoe.

Clamp the brake pads in a vise and use pliers to unhook the adjusting wedge return spring and the upper return spring. Remove both pads, as well as the pressure piece located at the top.

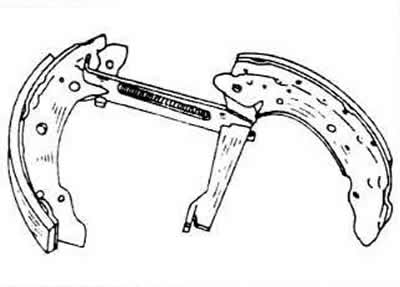

Clamp the brake shoes in a vise with the pressure piece placed between them and remove this part from the shoes until the spring is released and it can be unhooked and completely removed. Remove the installation wedge as well, but pay attention to how it is inserted.

Thoroughly clean all parts. With particular attention check the condition of the rubber caps of the brake cylinders. If wet areas are found, repair or replace the cylinder.

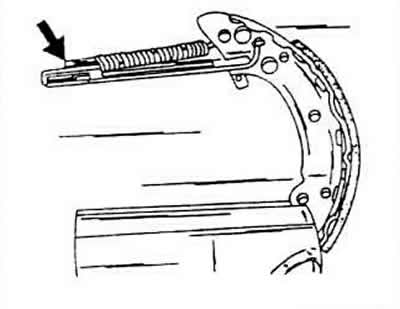

Clamp the pads in a vise, hang the spring and insert the pressure lever into the pads. Perform both manipulations at the same time. To do this, stretch the spring until then. until you can grab it.

Insert the adjusting wedge into the brake pads (in accordance with the previously shown mounting method) and assemble both pads. Hang the top return spring. To accurately hang the spring, look at the brake mounting diagram.

Hang the handbrake cable, open both brake shoes up and insert the upper ends of the shoes into the wheel brake cylinder pistons. without damaging the rubber cuffs.

Hang the lower return spring and place the left shoe on the support.

Hang the adjusting wedge return spring (forceps) and use a screwdriver to lift the block above the support.

Install the anchor pins in the reverse order of removal.

Mount the brake drum and adjust the clearance in the wheel bearing.

Apply the brakes several times to activate the additional adjustment mechanism.

Visitor comments