Dismantling

If the shock strut is to be disassembled, loosen the wheel and shaft nuts while the wheels are on the ground.

Put the car on jack stands and remove the wheels.

Unscrew the brake seat and tighten it with wire in a convenient place without unscrewing the seat from the hose.

Disconnect the self-locking swivel nut and push the ball bolt out with a puller.

Loosen the drive shaft flange screws on the inside. In this case, only a suitable set of wrenches should be used, otherwise the screw heads will be damaged.

On the inside of the lower transverse arm, unscrew the screw located on the side of the front side of the support. This screw fits into a threaded hole on the inside of the suspension cross member.

On the reverse side of the transverse arm, remove the lower screw.

From the underside of the transverse arm, remove the anti-roll bar nut. To do this, disconnect the nut and remove the leaf disk, as well as the rubber support. Pay attention to how both parts are put on.

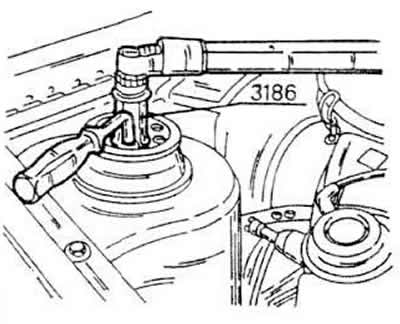

The suspension strut is now secured to the inside of the engine section. Remove the nut located in the middle of the suspension strut rod. However, since the piston rod can rotate during this, it is necessary to hold it. In car repair shops «Volkswagen» use a special key for this (3186), however, you can try using an Allen wrench and ring spanner to remove the nuts. The shock absorber strut will then be released and can fall out.

Remove the suspension strut and remove the transverse arm from the subframe.

Remove the top panel

Installation

Enter the suspension strut into the upper suspension; tighten the nut by hand.

Using the mounting collar, insert the front side of the transverse arm into the frame guide and slide on the rear side of the transverse arm.

Using a suitable drift, line up the threaded channel on the inside of the cross member and the transverse arm bore; screw in the screw Tighten the screw only by hand.

Insert the screw from the underside into the transverse arm rear support and hand-tighten as well.

Tighten the piston rod nut in the motor section; tightening torque is 60 Nm. At the same time, the rod should be kept from turning.

Attach the anti-roll bar.

Attach the drive shaft to the gearbox (together with reinforcing plates) and tighten the screws around to a tightening torque of 45 Nm. using a suitable set of keys.

Attach the tie rod to the rudder arm. New self-locking nuts must be used. Tighten them to a torque of 35 Nm.

Lower the car onto its wheels. Since you need to think about fixing the transverse arm, put the front wheels on the ramp. There must not be any additional cargo inside the car.

Both transverse arm screws (side and bottom) tighten to a torque of 130 Nm

Tighten the drive shaft nut to a torque of 265 Nm if the vehicle wheels are on the ground. Tighten the wheel screws to 110 Nm.

Visitor comments