Removal and installation of the lower transverse arm

The transverse arm can be dismantled in two ways. First, you can unscrew the transverse arm from the inside and disconnect the ball joint from the suspension strut. Secondly, you can unscrew the transverse arm from the inside, and then disconnect the screws connecting the ball joint and the transverse arm from the outside.

Loosen the wheel nuts and place the front of the car on the jack stands. Remove the wheel.

Using a jack, carefully lift the outer side of the control arm (under the wheel hub).

Dismantling the transverse arm together with the ball joint attached to it

Remove the screw connecting the outer side of the lever arm to the pivot pin, i.e. suspension joint clamping screw. To do this, loosen the nut and carefully drive out the screw. Handle the jack appropriately to compensate for the load.

From the inside of the lever arm in front, unscrew the side screw. The screw is pretty tight.

Remove the lower screw from the inside of the lever arm.

Disconnect the anti-roll bar from the transverse arm by unscrewing the nut from the underside. Remove the leaf disc and rubber support. Pay attention to that. how parts are mounted.

Lower the jack and push the control arm down until the ball joint trunnion comes out of the inside of the suspension strut.

Remove the lever arm. From the front side, push the transverse arm out of the support, and from the rear side, pull it out between the welded metal plate and the suspension subframe.

Dismantling without ball joint

On the outer side of the transverse arm from below, mark the contours of the ball joint plate. to then screw it in the same position.

Remove the three screws from the bottom of the ball joint plate and remove the locking plate with self-locking nuts from the top.

Push the shock strut outward slightly to disengage the connection.

Remove the side screw from the inside of the shoulder in front. The screw is pretty tight.

Remove the lower screw from the inside of the lever arm.

Lower the jack and push the control arm down (past ball joint plate).

Remove the lever arm. From the front side, push the transverse arm out of the support, and from the rear side, pull it out between the welded metal plate and the suspension subframe.

The transverse arm is mounted in the reverse order to dismantling. The tightening torque values can be found in the tightening torque table or in the various drawings showing the stages of installation.

Dismantling and installation of the anti-roll bar

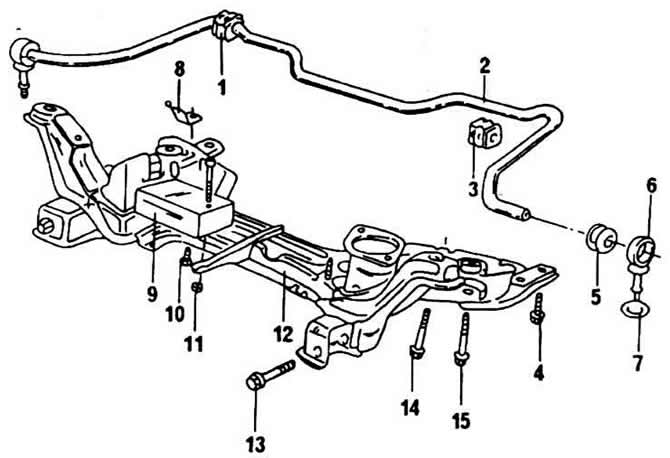

1 - rubber support sleeve on the subframe

2 - anti-roll bar

3 - rubber support sleeve on the subframe

4 - screw, 65 Nm

5 - rubber support at the end of the stabilizer

6 - connecting rod

7 - shaped washer, conical side facing the transverse lever

8 - mounting bracket

9 - vibration damper

10 - screw, 25 Nm

11 - nut, 25 Nm

12 - subframe

13 - screw M12x83, 50 Nm, then turn again by 90°

14 - screw M12x65, 70 Nm, then turn another 90°

15 - screw M12x78, 70 Nm, then turn another 90°

From the outside, the stabilizer is attached to the underside of the car with brackets and rubber mounts and is connected to the transverse arms with a connecting rod. The connecting rod is attached to the underside of the control arm with a nut. The sheet disk is embedded under the transverse arm and above it with a rubber support. When dismantling, you need to pay attention to the exact order of the location of the mentioned parts. The tapered surface of the rubber bushings are turned towards the sheet disc, respectively, while the sheet discs, with their beaded edges, are turned in the opposite direction from the bushings.

Visitor comments