Disconnect the wheel nuts and place the rear of the car on jack stands.

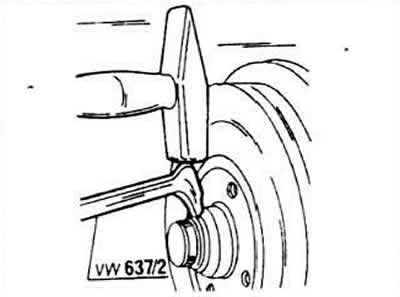

Remove wheel and cap. According to instructions. a special tool must be used, but the cap can be carefully removed with a screwdriver (shifting left and right alternately).

Remove the cotter pin from the nut lock and remove the locking device.

Loosen the adjusting nut and remove the washer.

For versions with drum brakes, remove the brake drum. This will release the outer bearing.

For versions with disc brakes, remove the brake seat (without opening the device) and remove the brake disc together with the hub. This will release the outer bearing.

Further, the disassembly process proceeds depending on the version.

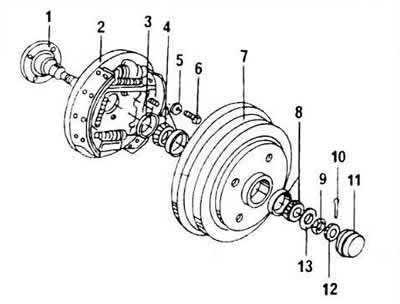

Vehicles with drum brakes

1 - axle end

2 - brake base plate

3 - oil sealing ring

4 - inner wheel bearing

5 - shaped washer

6 - screw, 60 Nm

7 - brake drum

8 - outer wheel bearing

9 - hex nut

10 - cotter pin, always replaced

11 - hub cap

12 - wrench lock

13 - thrust washer

Place the brake drum on an open vise, insert a mandrel from the front and knock out the rear bearing and grease seal. From opposite sides, knock out both working rings of the bearing from the drums.

Drive in new rings and lubricate the new bearing with grease.

Insert the inner bearing and, being careful, drive in the O-ring carefully. Wipe off any grease squeezed onto the surface.

Now you can reinstall the brake drum. These operations are not carried out on vehicles with a built-in anti-lock device.

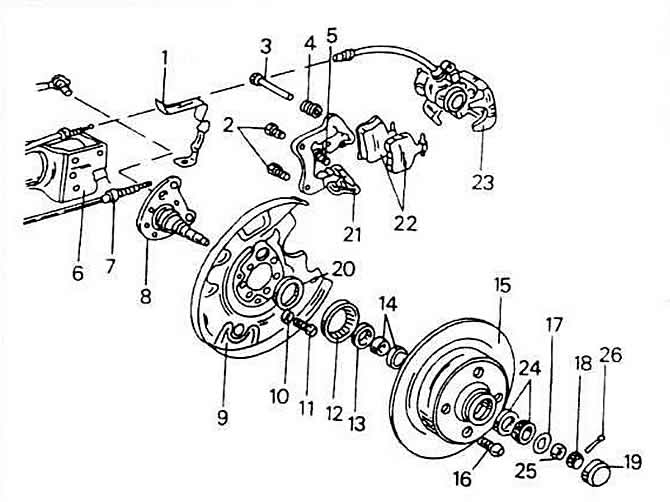

Vehicles with disc brakes

1 - fastening of a cable of a manual brake

2 - screws, 65 Nm

3 - guide bolt, brake seat

4 - protective cuff

5 - self-locking screw, 35 Nm

6 - spring clamp

7 - hand brake cable

8 - axle end

9 - mudguard

10 - shaped washer, convex side facing the mudguard

11 - screw, 60 Nm

12 - toothed crown of the anti-lock device

13 - grease sealing ring

14 - inner wheel bearing

15 wheels

16 - wheel screw, 110 Nm

17 - thrust washer

18 - wrench lock

19 - hub cap

20 - bearing cover

21 - brake seat support

22 - set of brake pads

23 - brake seat

24 - the outer ring of the bearing

25 - bearing adjusting nut

26 - cotter pin

Clamp the brake disc with a vise with tin or aluminum jaws and use a screwdriver to knock out the tin cap on the inside of the drum.

Place the inner side of the brake disc on the open vise jaws, insert the mandrel from the front and knock out the inner bearing together with the grease sealing ring. From opposite sides, knock both working rings out of the drum.

Clean both ends thoroughly.

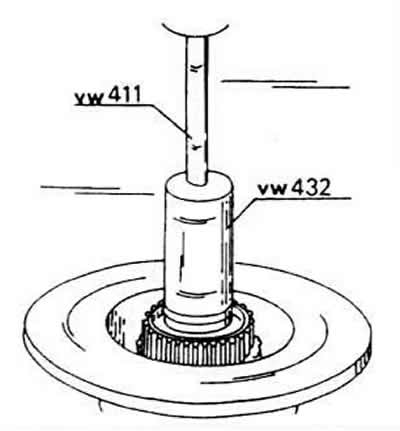

Assemble the new bearings as described for the drum brake version, but fit the brake disc together with the wheel hub over the vise opening to drive in the outer race of the inner wheel bearing. As can be seen from the figure, the crown of the anti-lock device is located on the brake disc, which must not be damaged. Insert the pipe section along the outer circumference of the bearing. Then flip the brake disc (hub) and drive in the outer ring of the wheel bearing in the same way. At the same time, do not push the wheel hub onto the surface of the drum, but seal it well from below, then a reliable stop will be provided when driving in.

Lubricate the wheel bearings well with grease, insert them from the back of the wheel hub and, being careful, drive in the grease sealing ring shown in fig. side until it sits securely. Look again to see if the crown was damaged during this operation.

Drive a tin cap with a mandrel of suitable diameter into the inside of the wheel hub without crushing it. Need to follow up on that. so that when replacing the wheel bearings, the ring gear intended for indicating speed is not damaged, i.e. the number of revolutions of the rear wheel related to the anti-lock device.

Move the brake disc to the end of the axle.

Mount all parts on the outside of the wheel hub.

Re-adjust the clearance in the bearings.

Tighten the nut firmly while the drum or brake disc rotates in different directions. This is necessary to insert the bearings into the working rings. Then loosen the nut again.

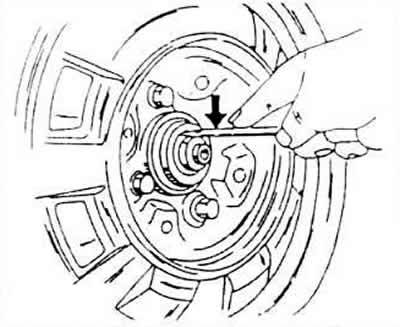

Tighten the nut again until the tip of the screwdriver can still move the disc under the nut from side to side.

In this position, insert the wrench and place a new cotter pin in it. If the cotter pin does not fit, you can slightly tighten the nut, however, remembering that after this operation the disc must be able to move freely.

Visitor comments