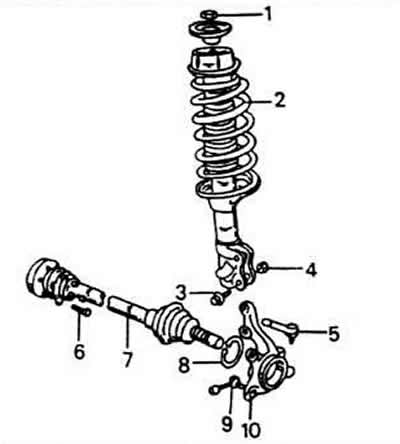

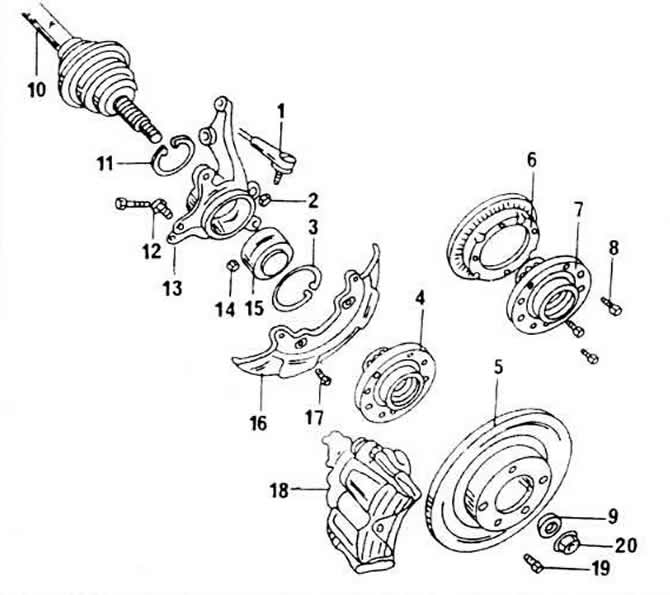

Elements of the front suspension strut together with the drive shaft and wheel bearing housing:

1 - self-locking nut, 60 Nm

2 - suspension strut

3 - for connecting the shock absorber with the pivot pin

4 - nut, 95 Nm

5 - tie rod

6 - stub axle screw, 45 Nm

7 - drive shaft

8 - bearing circlip

9 - brake seat screw, 125 Nm

10 - wheel bearing housing (stub axle)

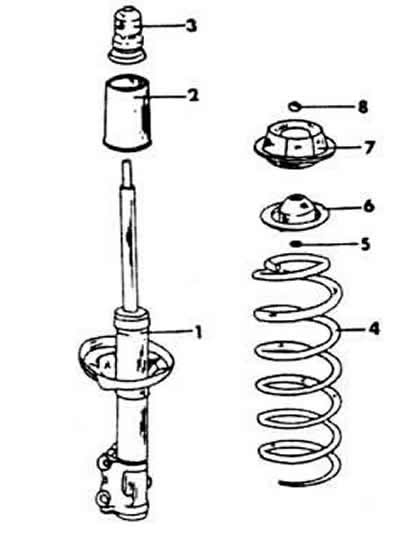

Mounting diagram of the front suspension strut:

1 - shock absorber

2 - protective cuff

3 - rubber stop

4 - screw spring

5 - washer

6 - upper spring seat

7 - suspension strut support

8 - slotted nut

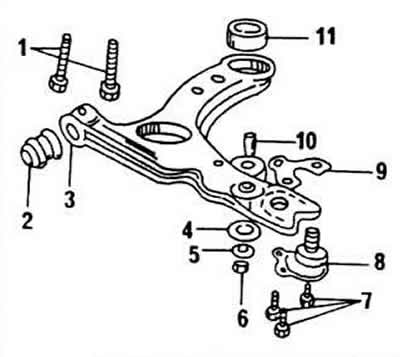

Removing the lower transverse arm

Completely unscrew the loose shaft nut and remove the washer.

Remove the brake disc from the wheel hub. It is attached with a separate screw.

Push the shaft out of the stub axle or knock it out with a rubber mallet. If a press is used, make sure that the wheel bearing housing is not damaged during this operation.

Disconnect the nut and screw that secure the transverse arm to the underside of the pivot pin.

Remove the transverse arm. If necessary, insert a screwdriver into the slot in the stub axle to make it easier to open the stub axle.

1 - subframe screws, 130 Nm

2 - front rubber support

3 - transverse lever

4 - rubber bushing for the connecting hoses of the anti-roll bar

5 - shaped washer

6 - nut for the connecting rod of the anti-roll bar, 25 Nm

7 - ball joint screws, 35 Nm

8 - suspension support hinge

9 - lock washer

10 - spring clip with safety pin

11 - rear rubber support

The way of fastening of the cross lever is shown in fig. Here you can also see the position of the rubber bushings.

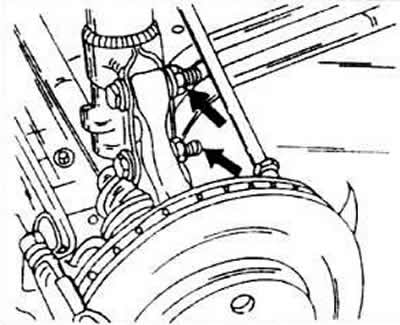

Removing the stub axle

Remove the nuts from both pivot pin screws on the underside of the suspension strut.

Carefully drive out the screws. It may turn out that they sit very tightly, as their rods are pinched. If the screws need to be replaced, remember that they provide the desired camber.

Insert a screwdriver behind the mounting shoulder of the wheel bearing housing and push the housing out of the suspension strut.

Check immediately if the threads of the screws have been damaged by knocking out. If this happens, replace the screws after measuring the camber.

Removing the wheel bearing

1 - tie rod

2 - nut, 50 Nm

3 - bearing circlip

4 - wheel hub

5 - brake disc

6 - toothed crown of the anti-lock device

7 - wheel hub with anti-lock device

8 - screws for fixing the ring gear

9 - thrust disc

10 - drive shaft

11 - snap ring

12 - brake seat screw, 125 Nm

13 - stub axle

14 - self-locking nut, 35 Nm

15 - wheel bearing

16 - mudguard

17 - screw, 10 Nm

18 - brake seat

19 - brake disc screw

20 - ointment hub cap

Note the crown screwed to the inside of the wheel hub and related to the ABS tachometer.

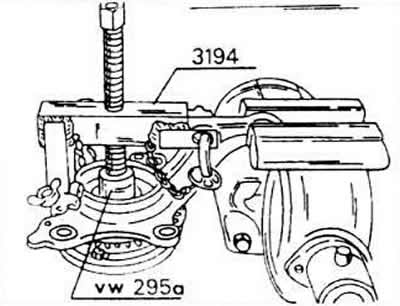

Place the wheel hub complete with bearing housing and mudguard under the press and carefully press it out using a suitable press mandrel. If a two-arm extractor is available, the surface trunnion can be pressed into the wheel hub from the bearing trunnion.

Unscrew the mudguard.

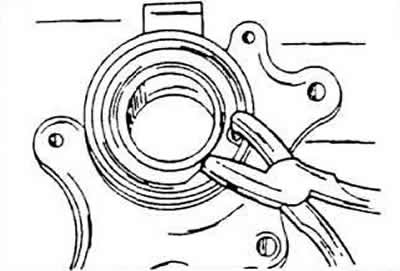

Remove the circlip located on the inside of the bearing housing, and then remove the outer circlip.

Press out the outer ring of the bearing, and position the bearing housing (stub axle) on the press table so that the mounting collar is facing up.

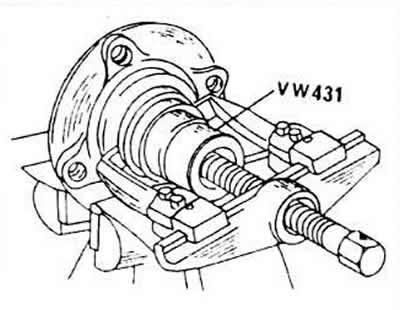

The inner ring of the bearing remains on the wheel hub; it must be removed using a suitable pull-out device.

if necessary, unscrew the crown of the anti-blocking device from the wheel hub; this is done only when replacing the crown or wheel hub.

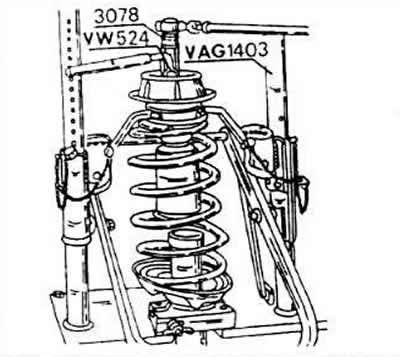

Coil springs and shock absorbers

Using a suitable spring clamp, tighten the spring until all tension in the spring is released.

Disconnect the nut located in the middle of the upper bearing. This is a slotted nut, which must be disconnected using a special wrench (3078). If this key cannot be obtained, unscrewing the nut can cause serious problems.

Remove the upper suspension strut bearing. You can only replace the entire bearing assembly at once.

Remove the top spring disc.

Remove the coil springs. There are various groups of tolerances for the dimensions of the springs. The springs themselves are marked with colored stripes. Therefore, when replacing springs, it is imperative to select two of them with the same marking marks. In no case should you install the first springs that come across, since they are designed for a certain engine weight, gearbox, appropriate road stability, etc., parameters that vary for individual models.

Lower the elastic rubber pad from the shock absorber piston rod. Pay attention to how it is put on the suspension strut, as its end parts are different.

Check shock absorber operation. To do this, clamp the lower end in a vise and try to remove and insert the piston rod. During the entire working stroke, the reaction force must be the same. In the event that the shock absorber was laid flat, it must be clamped in a vise before installation and pumped to remove all air from it. While doing so, slowly remove the damping device and reinsert it until the resistance is uniform. All air must be bled.

Visitor comments