Loosen the fasteners of the generator.

Remove the toothed belt.

Remove the steering belt protector.

Unscrew the pump pulley. To hold the belt pulley, you can insert the V-belt into the groove and press it down.

Loosen the clamps at the hose connections to the pump and pull out the hoses.

Disconnect the pump screws and remove it from the cylinder block. One O-ring is used under the water pump; it must be removed for inspection. Another O-ring seals the water inlet pipe in the pump casing.

The pump is installed in sequence. reverse dismantling. Tighten the pump and belt pulley screws to a torque of 20 Nm.

The water pump is beyond repair; if damaged, it must be replaced. Check for leaks after dismantling (the most common sign of it is the appearance of rust) and spin the hub to check the bearing.

To replace the pump, unscrew the thermostat housing from the underside and remove the thermostat. Disconnect the pump screws from the housing and remove the pump. Remove the seal between both body halves. The seal must be replaced.

When screwing the pump to the housing, replace the seal. Also replace the O-ring that seals the thermostat housing, even if it still looks good. Tighten the screws to the specified torque.

Water pump repair

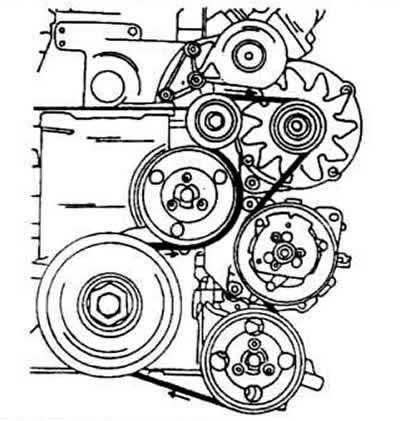

When considering the drive belt, here we are talking about consisting of a single whole belt for all units that are driven from the crankshaft pulley or, better, from the flywheel damper. This belt has ribs, hence one flat surface for application. It is provided with an appropriate pressing device which keeps the belt at the appropriate tension at any time. If you want to remove the drive belt, then the tensioner must be unloaded.

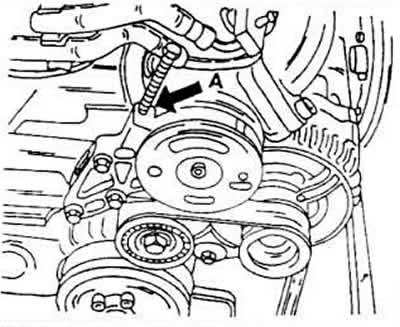

Bolt M8, screwed into the hole (A). This forces the tensioner away from the belt and makes the belt looser, allowing it to be removed.

On fig. shows how the drive belt "passes" on the units on the front side of the engine. When installing the belt, it is laid in the middle of all the rollers of the movement, and the bolt shown in fig. unscrews slowly. In this case, the tensioner changes its position relative to the belt and creates the prescribed tension.

After installing the belt, the engine starts and is allowed to run for a while. It is checked whether the belt drives well.

Visitor comments