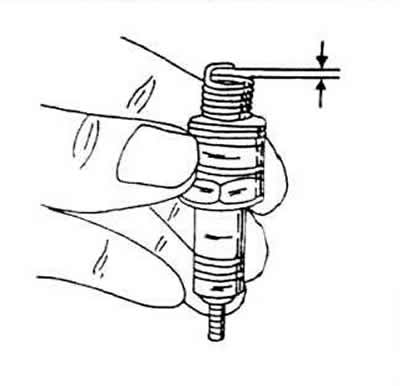

The distance between the electrodes of the candles is 0.7-0.8 mm and can be measured in the usual way.

Candles should be cleaned every 10,000 km of the car with a sandblasting compressor. In this case, an appropriate gap is established between the electrodes. When installing it, the middle electrode is never bent, as this may cause the porcelain insulator to burst

Before unscrewing the spark plugs, check if there are foreign bodies in the recesses of the spark plug body, washers, bolts, stone cutters and similar objects that fall into the spark plug hole when unscrewing it, can destroy valves, valve seats or cylinder head when the engine is first started.

By the appearance of the spark plug, conclusions can be drawn about its suitability and flawless operation, about the state of the mixture of fuel and air, as well as about the general condition of the engine (pistons, piston rings, etc.).

Candles in good condition

The thermal cone of the insulator is covered with a weak, often powdery precipitate, the color of which is from gray-yellow to brown. Electrodes, with the exception of combustion surfaces, have a powdery coating, the color of which ranges from gray-yellow to brown. The inside of the body has a coating that ranges from light brown or yellow to black-brown. The engine is fine. The heat value of the candle is chosen correctly.

Candle covered in soot

The thermal cone of the insulator, the electrodes and the inner part of the housing are often covered with a dense, powdery, black-gray, velvety coating. The reasons for this phenomenon are in the fatty mixture, in too little air, in non-compliance with the norms of thermal heating of the engine at idle, in too large a distance between the electrodes; candles have too high a glow number and remain cold during operation.

All electronic and electrical equipment of the engine should be checked, as there may be a malfunction somewhere. To help solve this problem, candles with different glow numbers were usually inserted in the past. However, you must establish with the help of the currently valid documentation which spark plug can be inserted, as spark plugs are very often replaced with each other in order to ensure the best combustion of fuel in the engine. At the moment, it is not possible to name any alternative suppositories that could be used to help.

Candle filled with oil

The thermal cone of the insulator, the electrodes and the inside of the housing are covered with greasy soot with an oily sheen: formation of oil soot. This could be caused by engine oil getting into the combustion chamber or onto closed cylinders and pistons. In your «Golf» this may only occur after a very many kilometers run, hence very rarely. In most cases, this means that the engine must be disassembled to find where the oil has entered. Associated with this are such inevitable troubles as replacing or restoring pistons, as well as grinding cylinders.

Overheating candle

The thermal cone of the insulator is covered with a vitreous or rough, hard caked deposit that is dark brown to grey-black in color, and often with a strong formation of deposits and granules at the end of the thermal cone. Traces of strong impact are visible on the electrodes. especially on average. The surface is often rough, swollen or corroded.

The reasons for this may be too lean mixture, loose candle, poorly closing valve; «guilty» there may also be a spark plug with a too low glow number, which is too hot because of this.

It would be useful in these cases to repair the cylinder head, as well as to achieve the engine running in accordance with the regulations.

Deposits between the middle electrode porcelain insulator and the spark plug body should be cleaned as best as possible with a sandblast.

When screwing in a candle, you should always pay attention to that. so that the thread of the candle is well cleaned beforehand.

Since the service life of the candle under normal conditions is at least 15,000 km, it is necessary to clean it every 10,000 km. When screwing in the spark plug, take care not to overtighten, as this could damage the sealing surfaces. The tightening torque of 25 Nm must not be exceeded, use a torque wrench for this purpose.

Visitor comments