If the valves have been ground in, they must be placed in the appropriate seats, since the wear pattern of all valves is different.

Lubricate the valve stems well with machine oil and insert them into their respective guides.

Using a collet, thread the lower plates of the valve springs through the valve guide from the other side.

Install the valve stem O-ring. A special tool is available for this.

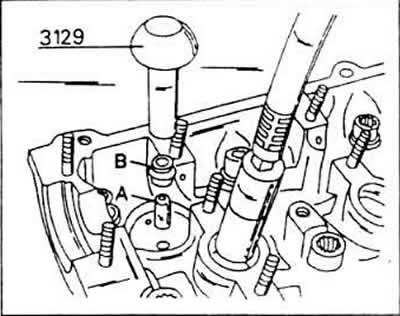

plastic sleeve (A) slide the special tool onto the protruding valve guide.

Lubricate the O-ring well (M) and thread it through the plastic sleeve.

Place tool 3129 on the o-ring and gently press it against the valve guide. Please note that without the use of the tool mentioned or similar, the stem O-rings may be damaged during installation; the result is increased oil consumption.

On the opposite side, place a piece of wood under each pair of valve heads to hold the valves in roughly the same position.

Fit the cylinder head with one inner and one outer spring of the corresponding valve (in case of reusing the same springs.

Install the upper valve springs. To compress the springs, use valve lifters, depending on whether the intake or exhaust valves are involved. If the end of the stem protrudes from the top spring cup, insert the valve cones into the stem slot and slowly raise the valve lifter back.

Use a plastic mallet to tap the valve stems from above, and the incorrectly seated valve half-cones will pop out. As a precaution, place a rag over the ends of the springs so that the disassembled parts cannot fly away from there.

Lubricate the bearing pins of both camshafts well with oil.

Both gears of camshafts engage with the drive chain.

Put on the drive chain in such a way that the direction of movement of the chain, marked with a special sign, is correct.

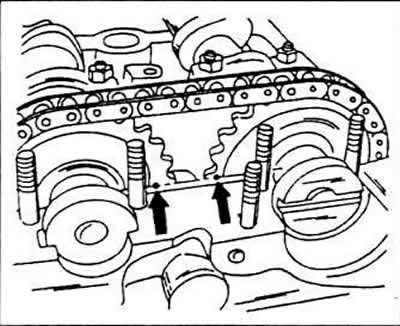

Align the chain sprockets so that both dot marks lie opposite each other and intersect with the edge of the cylinder head.

Insert the camshafts into the bearing holes and turn several times. Then turn the shafts until both marks are aligned.

Straighten the bearing caps of both camshafts, i.e. the notches on the covers must face the inlet side of the cylinder head accordingly.

Install the intake valve shaft. To do this, put on the bearing caps No. 6 and No. 8 evenly, tighten the nuts crosswise to a tightening torque of 15 Nm.

Position the remaining bearing caps correctly and tighten evenly to a torque of 15 Nm.

Install the exhaust valve shaft. To do this, put on the bearing caps No. 2 and No. 4 evenly, tighten the nuts crosswise to a tightening torque of 15 Nm.

Position the remaining bearing caps correctly and tighten evenly to a torque of 15 Nm.

Pick up the camshaft sealing ring and determine which side the spring is on. Orient the ring with the spring facing inward and lightly oil the sealing lip and also the shaft running surface. To install a new oil seal ring, use a piece of pipe of a suitable diameter. The pipe must be completely pushed onto the outer perimeter of the O-ring. Bring the sealing ring without distortion and drive it in until it rests against the outer surface with a shoulder. It is also possible to insert the oil seal ring in the manner described for replacing the crankshaft front seal ring.

Put the camshaft flywheel on the shaft (don't forget the pin) and screw in the screw with washer. Hold the flywheel in a convenient way for you (e.g. using an old toothed belt) and tighten the screw to a torque of 65 Nm.

Rotate both camshafts several times to check for pinches.

Mount all parts installed in the cylinder head.

Mount the exhaust port in the cylinder head (use new seals). The suction duct is screwed on when mounting the cylinder head.

Visitor comments