Disconnect the top screws between the engine and gearbox.

Separate the tachometer drive from the gearbox.

Disconnect and remove the upper starter mounting screw.

Switch the lever to position (R) and separate the cable that lubricates the lever and gearbox.

Detach the cable support and remove it.

Remove the engine from the mount by raising it with a lifting device so that it is under tension.

Place the front of the car on jack stands and unscrew the bottom shield from under the engine.

Disconnect the screws of the left suspension and completely dismantle the suspension.

Clamp the oil supply hoses with suitable ferrules and disconnect the hose ends from the radiator.

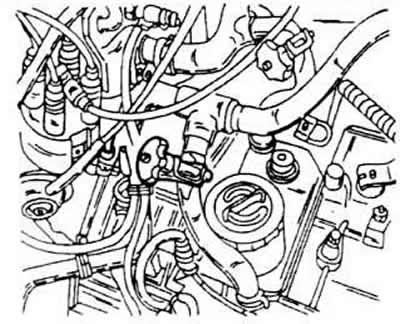

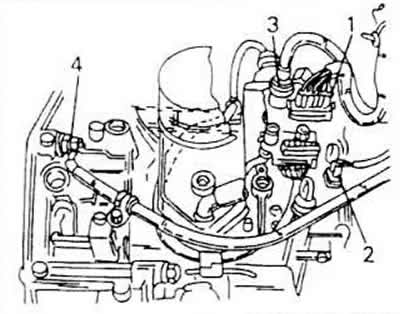

Disconnect the electrical connections shown in fig.

Unscrew the protective plate of the transmission oil pan.

Disconnect the front engine mount and completely dismantle it. Now dismantle also the starter.

Flange the primary halls of the gearbox and tie the right shaft in a convenient place with a piece of wire.

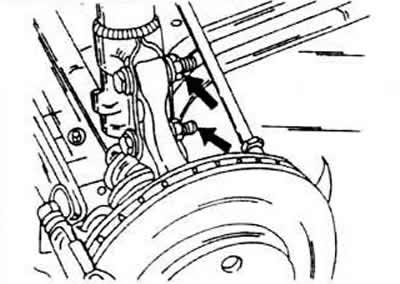

Completely dismantle the left input shaft. To do this, loosen the input shaft nut and unscrew the front wheel. Using a scriber, mark the position in which the wheel bearing housing was installed relative to the suspension strut, and remove the screws shown in fig. Disengage the wheel bearing housing and rock to the side until the shaft can disengage from the wheel hub.

Unscrew the protective cover from under the torque converter.

Through the opened hole, alternately unscrew the screws located between the drive plate on the crankshaft and the torque converter. To do this, turn the crankshaft. until the screws appear one by one.

Place a jack under the gearbox and disconnect the rubber-metal bearing screws.

Raise the engine a little higher. This will lower the gearbox and make it easier to dismantle it.

Disconnect the bottom screws between the engine and gearbox.

Carefully lower the gearbox and disconnect from the engine. Secure the torque converter to the gearbox so that it cannot fall out. Make sure that the input shafts and the tachometer drive are not damaged. The gearbox is mounted in the reverse order to dismantling, taking into account the following aspects.

Tighten the torque converter screws on the drive plate to a tightening torque of 60 Nm.

Tighten the screw connection between the engine and gearbox to a torque of 80 Nm (M12 screws) or 60 Nm (M10 screws).

Install the front bracket on the hydraulic suspension and tighten it to a torque of 60 Nm.

Install the bracket on the left hanger and tighten the screws to a torque of 60 Nm.

Install the bracket on the left side of the gearbox and tighten the screws to a torque of 25 Nm.

Attach the protective cover to the gearbox. Tighten the screws to a torque of 15 Nm.

Re-engage the left input shaft.

Re-mount the wheel bearing housing, align the marked markings and tighten the connecting screws to a torque of 95 Nm.

Tighten the input shaft nut to a torque of 265 Nm after the vehicle wheels are back on the floor.

Tighten the input shaft screws from the inside to a tightening torque of 45 Nm.

Visitor comments