Removing

The gearbox can be removed from the underside of the vehicle, so the body must be properly jacked up. This requires a mobile car jack to support the gearbox. It doesn't matter how the body will be mounted on the goats, but you should always take into account the fact that powerful dummy goats should be installed under the frame.

Disconnect the negative cable from the battery. If a radio station is installed, then you need to know the code for the anti-theft protection system. Before doing this, turn off the ignition (you have to wait after turning off 20 seconds).

Install a car jack under the gearbox. Even better, if you can lift the engine from the suspensions using a lifting mechanism and a cable.

Be sure to disconnect all electrical cables from the transmission.

Disconnect the shift cables from the side of the gearbox and unscrew the bracket on the side of the box.

To remove the clutch receiver cylinder, it is necessary to unscrew the shift cable with a handle from the gearbox wall.

Disconnect the tachometer coil spring from the transmission.

Loosen the bolts between the engine and gearbox on the top side.

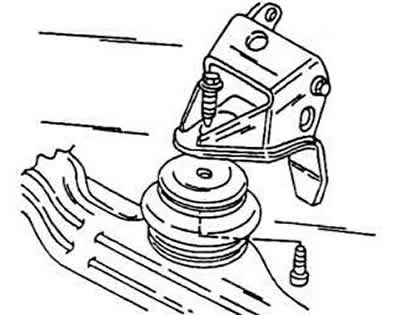

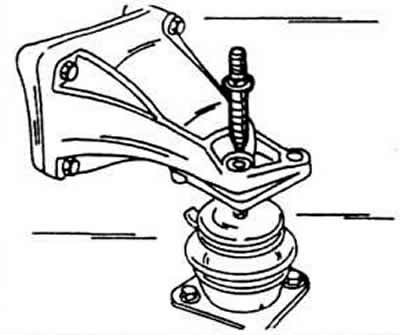

Unscrew the stand and rubber-metal support.

Unscrew the bolt from the lower rubber-metal support. Since the anti-lock brake system is installed, access to these bolts is quite difficult. If this is still required, then it is necessary to remove the expansion vessel of the cooling system. After that, carefully remove the bolts using an interchangeable socket wrench with an extension and a cross joint.

Loosen the front bracket bolt.

Now, with the help of a lifting mechanism, the engine is lifted from the suspensions. Pay attention to the fact that not a single part remains under mechanical stress or force.

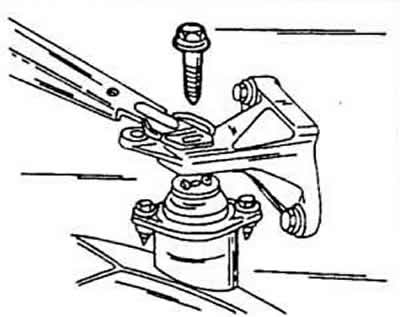

Remove the starter and front bracket.

Slide the power steering hoses onto the rubber mounts on the front bracket and secure them to them.

Unscrew the subframe counterweight.

If a thermal insulation sheet is installed for the inner right CV joint, unscrew it from the motor.

Unscrew the left and right drive shafts on the inside. For these bolts, it is imperative to use a suitable set of wrenches, as they have multi-toothed heads with internal grooves.

Turn the wheels to the right until they stop. Tie the shafts tightly with string or wire in an appropriate manner to keep them out of the way.

Remove the gearbox mounts and the suspension bracket from the gearbox. Press the engine and gearbox from the frontal side and unscrew the lower bolt from the suspension bracket.

Unscrew the cover plate under the flywheel housing.

Remove all bottom bolts between engine and transmission.

Using a tire spatula, press the gearbox away from the engine and remove the gearbox. This requires two people.

Place the gearbox carefully on the floor.

Installation

The gearbox is installed in the reverse order of removing the gearbox, subject to the following points.

Apply graphite powder to the small splines of the drive shaft.

Press the clutch release lever towards the gearbox housing and secure it with a 22 mm M8 bolt. After installing the gearbox, remove this bolt and plug the hole.

Mount all transmission and engine mountings without mechanical stress.

Set up a connection.

Tighten the bolts between the engine and gearbox with a tightening torque of 80 Nm. All other tightening torques are given in the tables of dimensions and adjustments.

Visitor comments